Initial Dyno Results - Buschur Ported Bits

#1

Initial Dyno Results - Buschur Ported Bits

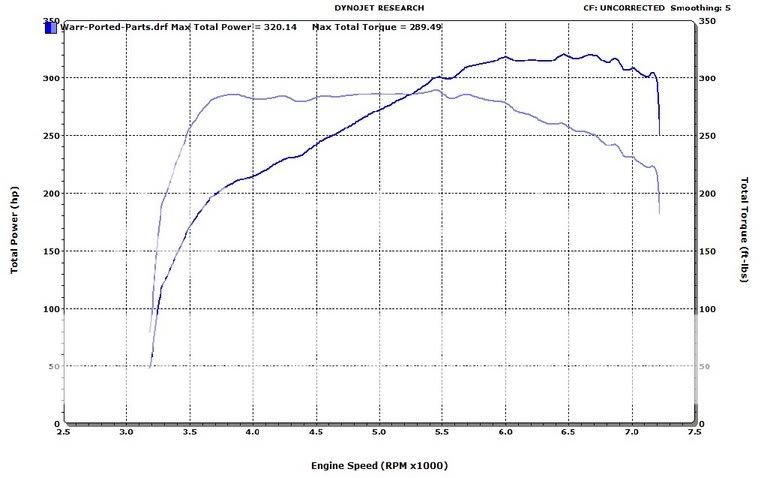

Don't feel like typing a ton, but here's my not-so-high results from today. I'm experiencing a problem with getting the proper boost now with the Forge WGA installed, but I haven't yet troubleshot the problem. I'm basically getting base WG pressure even if I crank the MBC 30 clicks, so I either have something hooked up wrong, or the WGA isn't adjusted properly. Basically, I can't get over 19psi, and the initial boost "spike" is non-existent. It very quickly jumps to 18psi, but then slow rises to 19 and then almost 20psi...holds...then tapers to 19psi at around 7k rpm, but no lower. You can see it in my torque curve. Instead of torque jumping up high at peak boost, then linearly tapering down, mine rounds off at peak boost, and goes flat...even rises slightly (peak at 5500), then doesn't start to drop off until 6k rpm. The amount of time above 300whp is pretty good, so my overal power didn't suffer terribly, but my initial torque and resulting power curves took a big hit with the 18psi spike instead of my normal 22psi spike. Just 2 days ago before the ported stuff, WGA, and filter, my torque hit at 3600-3700 was violent. Now, it's gradual like a supercharger (not quite, but you get the idea).

I need to figure out if it's my install error, or WGA adjustment error, or not enough turns on the UNOS MBC (soft spring), or the ported exhaust parts affecting spool, etc. My timing at peak torque was great, and my tune wasn't far off despite not being designed for these parts, but I'd love to see what a solid 21-22psi would do in my current state.

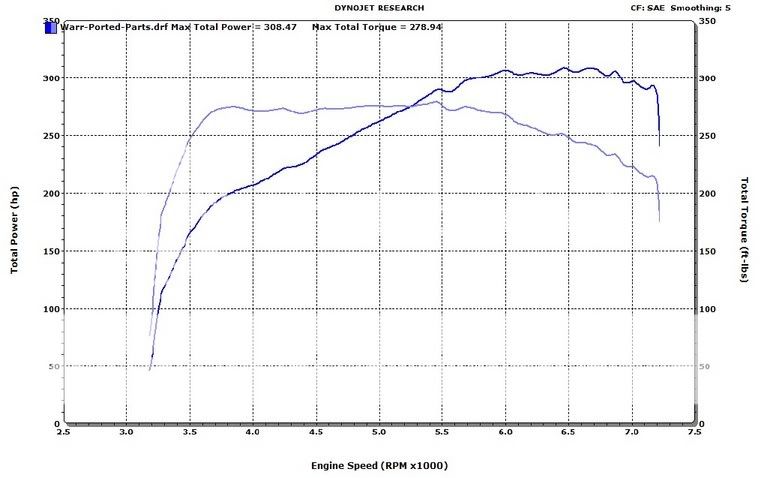

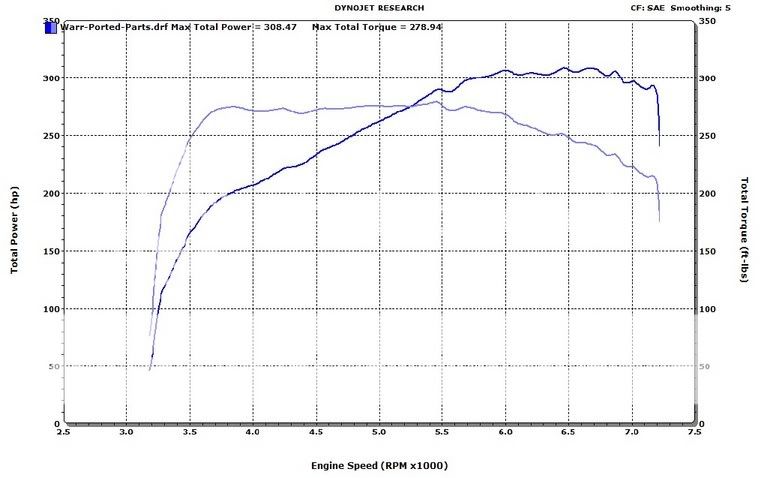

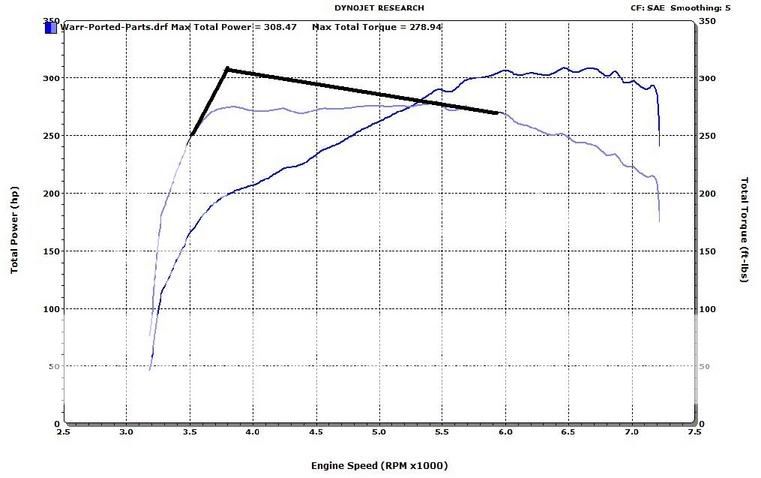

SAE corrected numbers 308whp/278wtq:

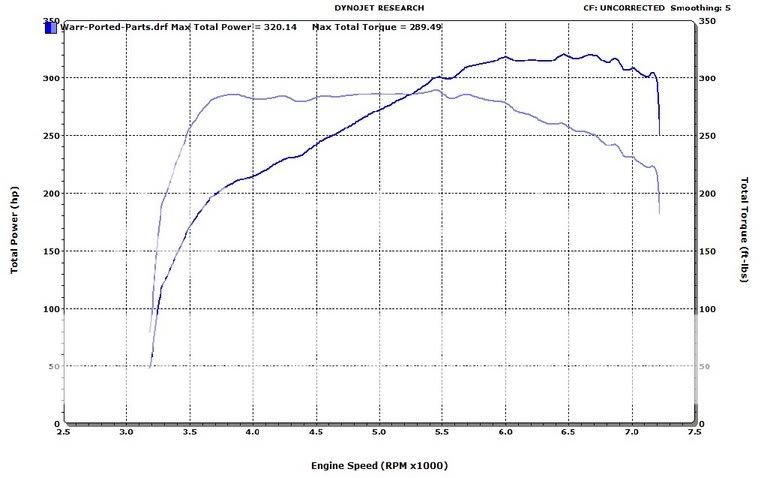

UNCORRECTED numbers (I plan to use these from now on, because I don't like how it tries to account for temps and/or altitude, especially since I'll be in CO at 6000' where they use a huge correction factor. I will only compare uncorrected from now on so that I know EXACTLY what I'm putting down regardless of the conditions. I don't care about comparing to other dynos around the country.):

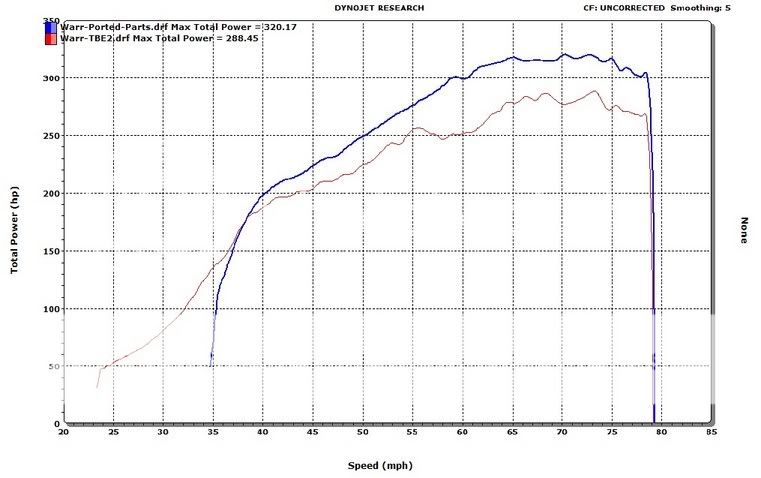

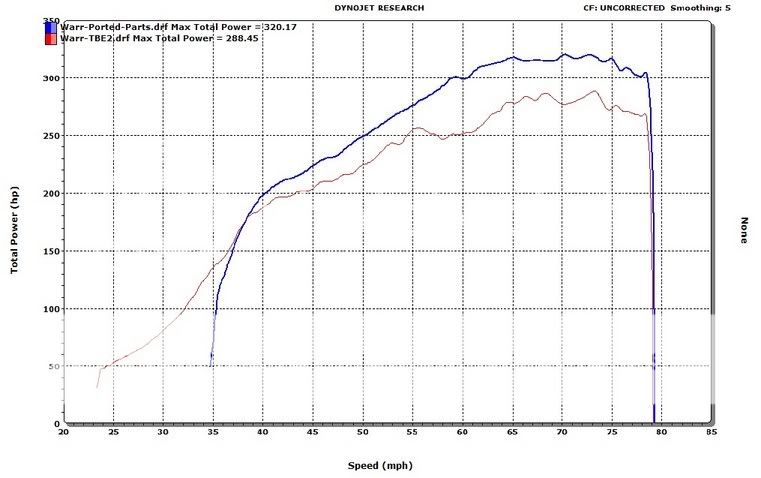

Previous dyno tuned on SAFC at 21-22psi vs. same setup plus Dynoflash and ported parts at only 19-20psi:

For reference with other cars today on the same dyno (all SAE):

05 w/cams, catless tbe, mbc@23psi, bov, intake, megan mani, megan o2, dynoflash = 335whp/340wtq (SAE)

05 w/cams, catless tbe, mbc, bov, intake, dynoflash = 321whp

05 w/cams, catless tbe, mbc, bov, safc = 313whp

05 w/catless tbe, ebc, bov, intake, megan mani, ams fmic, safc = 310whp

Warr w/catless tbe, mbc, bov, intake, p/p stock mani, p/p stock turbine, ebay o2, dynoflash (tuned for previous mods) = 308whp/278wtq

There were 2 cammed 03s that did 290whp and 285whp, but I don't know the mods other than tbe/mbc.

So, comparatively, i did well, but I was the only one with such low boost and only flashed car with terrible peak torque. Mine was 30 below my HP due to the mild onset of boost while they all had equal or greater torque than HP. If I resolve this tomorrow, I will drive back out and dyno myself in a solo session.

I need to figure out if it's my install error, or WGA adjustment error, or not enough turns on the UNOS MBC (soft spring), or the ported exhaust parts affecting spool, etc. My timing at peak torque was great, and my tune wasn't far off despite not being designed for these parts, but I'd love to see what a solid 21-22psi would do in my current state.

SAE corrected numbers 308whp/278wtq:

UNCORRECTED numbers (I plan to use these from now on, because I don't like how it tries to account for temps and/or altitude, especially since I'll be in CO at 6000' where they use a huge correction factor. I will only compare uncorrected from now on so that I know EXACTLY what I'm putting down regardless of the conditions. I don't care about comparing to other dynos around the country.):

Previous dyno tuned on SAFC at 21-22psi vs. same setup plus Dynoflash and ported parts at only 19-20psi:

For reference with other cars today on the same dyno (all SAE):

05 w/cams, catless tbe, mbc@23psi, bov, intake, megan mani, megan o2, dynoflash = 335whp/340wtq (SAE)

05 w/cams, catless tbe, mbc, bov, intake, dynoflash = 321whp

05 w/cams, catless tbe, mbc, bov, safc = 313whp

05 w/catless tbe, ebc, bov, intake, megan mani, ams fmic, safc = 310whp

Warr w/catless tbe, mbc, bov, intake, p/p stock mani, p/p stock turbine, ebay o2, dynoflash (tuned for previous mods) = 308whp/278wtq

There were 2 cammed 03s that did 290whp and 285whp, but I don't know the mods other than tbe/mbc.

So, comparatively, i did well, but I was the only one with such low boost and only flashed car with terrible peak torque. Mine was 30 below my HP due to the mild onset of boost while they all had equal or greater torque than HP. If I resolve this tomorrow, I will drive back out and dyno myself in a solo session.

Last edited by Warrtalon; Jan 15, 2006 at 09:40 PM.

#3

Evolved Member

iTrader: (40)

Warr,

on my tune my boost was dropping to 19 PSI, but I was spiking to 24.5.... with my boost leak. As far as the forge wastegate goes, they told me that they had to "pretension it" like 4 turns before installing it onto and over the wastegate flapper...

what kinda dynojet numbers are those??? looks kinda low to me

on my tune my boost was dropping to 19 PSI, but I was spiking to 24.5.... with my boost leak. As far as the forge wastegate goes, they told me that they had to "pretension it" like 4 turns before installing it onto and over the wastegate flapper...

what kinda dynojet numbers are those??? looks kinda low to me

#4

Evolved Member

iTrader: (42)

Join Date: Aug 2005

Location: St. Charles, IL

Posts: 2,502

Likes: 0

Received 0 Likes

on

0 Posts

Looks pretty good. Did you have to change the settings much on the afc?

Just for reference the unos is like 85 clicks from one end to the other, With the stock WGA I didn't notice the boost really go up very much until I was near the end...

Now Im curious to see how you do with the dynoflash/alky

Thanks for sharing

Just for reference the unos is like 85 clicks from one end to the other, With the stock WGA I didn't notice the boost really go up very much until I was near the end...

Now Im curious to see how you do with the dynoflash/alky

Thanks for sharing

#5

Originally Posted by Blue Evo 8

on my tune my boost was dropping to 19 PSI, but I was spiking to 24.5.... with my boost leak. As far as the forge wastegate goes, they told me that they had to "pretension it" like 4 turns before installing it onto and over the wastegate flapper...

what kinda dynojet numbers are those??? looks kinda low to me

what kinda dynojet numbers are those??? looks kinda low to me

You do have to pretension it, and I checked to make sure mine was, but it was only pretensioned by like a millimeter. I could almost put the wastegate arm directly on the flapper pin. I don't know if that's after 4 turns already, or if I need to go 4 turns from here or what. I missed that part of the install while buying oil at the store for the re-installation of everything. I have to test the MBC stuff more first, then I will mess with the WGA arm if necessary.

Yes, the numbers are from a Dynojet and are fairly low, but then again, they're always a good bit lower than similar cars at TT, and we don't know why. You can be sure that our track times are not low...

#7

Originally Posted by Boltz.

Looks pretty good. Did you have to change the settings much on the afc?

Just for reference the unos is like 85 clicks from one end to the other, With the stock WGA I didn't notice the boost really go up very much until I was near the end...

Now Im curious to see how you do with the dynoflash/alky

Thanks for sharing

Just for reference the unos is like 85 clicks from one end to the other, With the stock WGA I didn't notice the boost really go up very much until I was near the end...

Now Im curious to see how you do with the dynoflash/alky

Thanks for sharing

Trending Topics

#8

Originally Posted by evo robert

whoa that torque curve looks awesome! the majority of dyno graphs i've seen on this site just have a nasty fall off, yours is damn good!

Here is a crude, extrapolated example, and this is still only if I was spiking right at a full 20psi instead of 18. If I could spike to 22-23, you might see that whole torque curve push up another 10-15 across the board...

#9

Evolved Member

iTrader: (40)

Originally Posted by Warrtalon

So you have the Forge WGA on there, too? I don't get a spike at all and don't ever get close to 24psi, but maybe it's just because I'm too low on the soft spring like Boltz said. I never bothered with the soft spring at anywhere less than the full 90 clicks, so I am not sure how it responds at 20-30clicks. It may just be a case of me continuing ot turn it until it starts to responds at initial spoolup.

Funny thing though I didnt raise the warning on my EBC higher than 24.5 and no mater what we tried we couldnt hit 28..... so what Keith from TT did was crimp one of my wastegate lines shut (taking the HKS EBC out of the equation) with a set of pliars, and Mark did another run....voila I spike to 27.5 PSI.....but obviosly with a boost leak I was losing it real quick

You do have to pretension it, and I checked to make sure mine was, but it was only pretensioned by like a millimeter. I could almost put the wastegate arm directly on the flapper pin. I don't know if that's after 4 turns already, or if I need to go 4 turns from here or what. I missed that part of the install while buying oil at the store for the re-installation of everything. I have to test the MBC stuff more first, then I will mess with the WGA arm if necessary.

well, I'm guessing you were a bit too conservative on the pretension. The TT guys made their 4 turns on the wastegate arm and actually made it tight, and then had to stretch it a bit to get it over and onto the wastegate flapper....

When i had my SRT4 I did this as well... I had to turn the screw in a few notches and then pull, with a little bit of force the wastgate arm over the flapper. then I went out and did some test runs on the SRT$ to see that I was holding at least 13-14 PSI by redline without the help of an EBC/MBC

Yes, the numbers are from a Dynojet and are fairly low, but then again, they're always a good bit lower than similar cars at TT, and we don't know why. You can be sure that our track times are not low...

Yep

#10

Evolved Member

iTrader: (6)

when you attached the wastegate actuator was there any tension on it? on my actuator I adjusted the turn buckle all the way down then pulled on it to attach it to the wastegate. It was like putting on a rubber band. when I installed it without any tension I had the same exact problems your describing.

#11

Evolved Member

iTrader: (40)

Originally Posted by joeymia

when you attached the wastegate actuator was there any tension on it? on my actuator I adjusted the turn buckle all the way down then pulled on it to attach it to the wastegate. It was like putting on a rubber band. when I installed it without any tension I had the same exact problems your describing.

exactly

exactly

#12

Originally Posted by joeymia

when you attached the wastegate actuator was there any tension on it? on my actuator I adjusted the turn buckle all the way down then pulled on it to attach it to the wastegate. It was like putting on a rubber band. when I installed it without any tension I had the same exact problems your describing.

#14

Originally Posted by Rollaway

War... when you installed the wg did the end fit easily to the back housing?... if so than its too loose..

If by "back housing", you mean the wastegate flapper, then no, I couldn't get it on by hand, but I didn't have to pull the arm very far to get it on the flapper pin (millimeter or so). This is what I was referring to in the earlier responses - hopefully, that's what you were asking about...