boring cylinders

#1

Newbie

Thread Starter

Join Date: Jun 2007

Location: Tampa, Florida

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

boring cylinders

I have new wiseco pistons just waiting to be installed in my engine but I need to get machining done

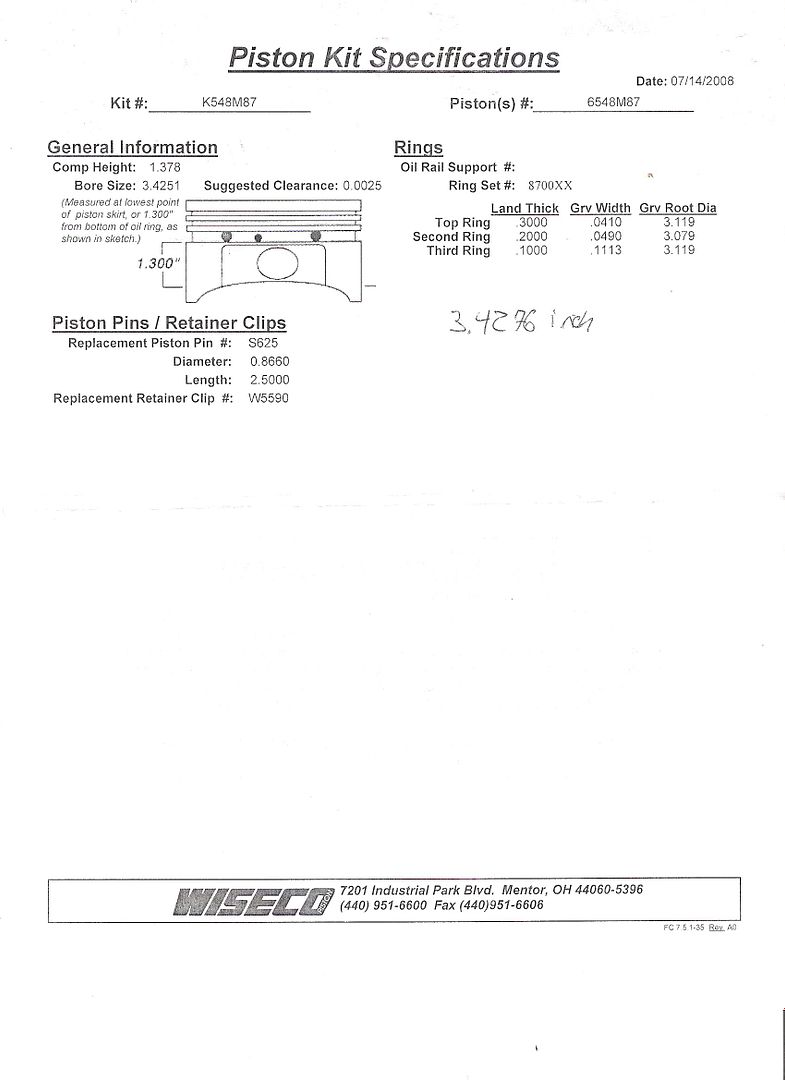

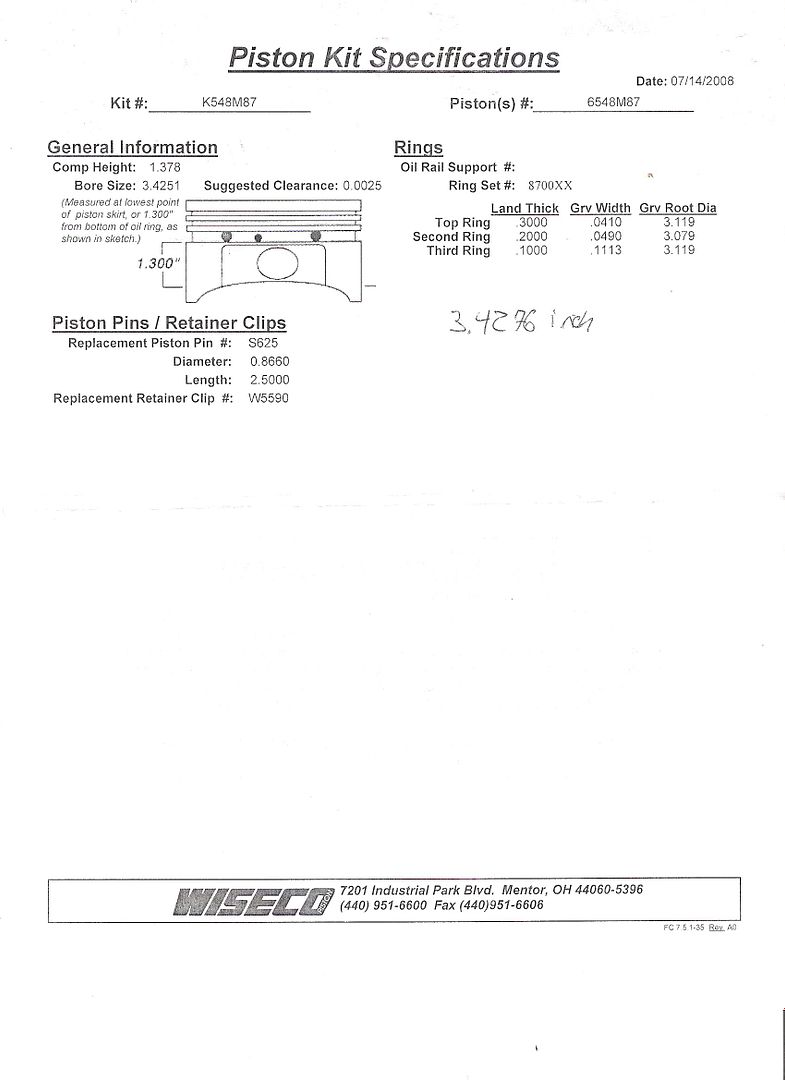

Im not sure but on the spec sheet wiseco gave me there is...

bore size 3.4251 in and

suggested clearance of .0025 in

That would make the size i need to ream my cylinders to 3.4276 in

just need to 100% positive on anything Im doing, got only 1 block

Im not sure but on the spec sheet wiseco gave me there is...

bore size 3.4251 in and

suggested clearance of .0025 in

That would make the size i need to ream my cylinders to 3.4276 in

just need to 100% positive on anything Im doing, got only 1 block

#3

Newbie

Thread Starter

Join Date: Jun 2007

Location: Tampa, Florida

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

The machinist im giving it to uses standard, i talked to slowboy racing and bought rod/pistons combo, I wasn't asked std/metric from SBR. I knew i wanted my bore to be 87mm, .020 over my stock (which is 86.5mm for my 4G64 block). Wiseco probably uses standard more often than not, especially in america where most machining is standard. I wanted oversized pistons and rings because my engine had 85k miles on it, which probably caused a lot of wear to my engine, I took the safe way and am getting it all machined perfectly, instead of buying all stock then burning oil due to worn cylinder walls and crank misplacement (or walking) due to stock bearings on a worn crank mains.

I wasn't surprised it was standard, I just need to know the exact # in inches to tell my machinist to ream it out to.

The bore size on the spec sheet (3.4251 in OR 87 mm) is the exact size of my wiseco pistons...correct?

and suggested clearance (.0025 in) would be the size of the space between cylinder wall and piston...correct?

Which would inturn make my cylinders needed to be reamed out to

3.4276in .... correct?

just trying to be certain.

I wasn't surprised it was standard, I just need to know the exact # in inches to tell my machinist to ream it out to.

The bore size on the spec sheet (3.4251 in OR 87 mm) is the exact size of my wiseco pistons...correct?

and suggested clearance (.0025 in) would be the size of the space between cylinder wall and piston...correct?

Which would inturn make my cylinders needed to be reamed out to

3.4276in .... correct?

just trying to be certain.

#5

Evolving Member

iTrader: (7)

Your bore needs to be finished to 87mm. The clearance is already provided in the piston design, you just need to finish your bore to the recommended size (3.4251"). If you measure your pistons with a good micrometer at the recommended point on the piston skirt, you will find that they are about .0025" under the recommended bore size on the spec sheet.

Many people measure each piston first, then fit each piston to the bore to ensure the exact piston to wall clearance desired. This is to compensate for the manufactures tolerance (could be up to .0008" or more for low quality parts). Your pistons should be pretty close to measuring at 3.4226".

If you plan on running at wide open throttle for longer durations, you may want to add more piston to wall clearance, but that's another conversation.

Good luck!

Many people measure each piston first, then fit each piston to the bore to ensure the exact piston to wall clearance desired. This is to compensate for the manufactures tolerance (could be up to .0008" or more for low quality parts). Your pistons should be pretty close to measuring at 3.4226".

If you plan on running at wide open throttle for longer durations, you may want to add more piston to wall clearance, but that's another conversation.

Good luck!

Trending Topics

#10

Evolving Member

iTrader: (8)

Join Date: Feb 2006

Location: Midland, TX

Posts: 369

Likes: 0

Received 0 Likes

on

0 Posts

that's not ring gap. that's...not something we measure, so I don't even know what to call that. Probably...touching...that's a good word. Your top ring should be about nothing from the wall, or "touching" as they say in the industry.

Your ring GAP depending on your bore and desired application can be found through the simple math on the sheet that came with the pistons. For a mild street turbo evo about .005"/in of bore for the top and .0055"/in. of bore for the second. But for a more extreme setup you would want .006'/in. or more.

For the OP, perhaps a little late, but I hope you went with a bit more than .0025'' piston to wall, that sounds awfully tight to me.

Your ring GAP depending on your bore and desired application can be found through the simple math on the sheet that came with the pistons. For a mild street turbo evo about .005"/in of bore for the top and .0055"/in. of bore for the second. But for a more extreme setup you would want .006'/in. or more.

For the OP, perhaps a little late, but I hope you went with a bit more than .0025'' piston to wall, that sounds awfully tight to me.

#11

Evolving Member

Join Date: Sep 2009

Location: long island

Posts: 135

Likes: 0

Received 0 Likes

on

0 Posts

on the wiseco's im installing into my machined block i had them make my piston to wall clearance .004. But this set lists the bore @ 3.3858, for reference i measured them at 3.3545 (85.21mm) at 1.3in from the bottom of the oil ring groove, as per wiseco's instructions.

Wiseco lists their suggested ptw clearance @ .0025, but this is just a starting point for you depending on certain variables of your build (such as how much boost you plan to run).

Not to jack the thread, but could someone knowledgeable suggest a ring end gap, as ive been on hold with wiseco for an hour and 20 min.

Wiseco lists their suggested ptw clearance @ .0025, but this is just a starting point for you depending on certain variables of your build (such as how much boost you plan to run).

Not to jack the thread, but could someone knowledgeable suggest a ring end gap, as ive been on hold with wiseco for an hour and 20 min.

#12

You don't need to tell your machine shop what exactly to bore to. You need to give your machine shop the block and the pistons, and the spec sheet, and they will measure the pistons and bore accordingly.

Thread

Thread Starter

Forum

Replies

Last Post

WTB[SouthEast]: .020 or .040 over pistons

Evo47

For Sale/WTB - Engine / Drivetrain / Power

0

Feb 4, 2017 09:38 PM

tscompusa

Evo Engine / Turbo / Drivetrain

158

Jan 17, 2017 02:52 PM

My03evo

Evo Engine / Turbo / Drivetrain

17

Oct 10, 2012 12:14 AM

Perk77

General Engine Management / Tuning Forum

3

Aug 28, 2008 07:59 PM