my intake cam snapped?!!?

#196

Newbie

Join Date: Jun 2007

Location: Christchurch, NZ

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

Get your facts right.

Firstly, like I said in the e mail that someone posted. We never used the 'Japan' core when it was made from Ductile Iron, so we never had the hard facing issue that other companies had. Also, I do not have a quiry from you on this, so why are you confusing the issue here?

#197

Evolved Member

iTrader: (67)

Join Date: May 2006

Location: FL

Posts: 753

Likes: 0

Received 0 Likes

on

0 Posts

I would like to test the rockwell between the stock cam and the broken cam.

If anyone want's to send me a stock cam and a broken cam Like the op I would be willing to test and share the results.

There is a few other things I can test as well such as a magnaflux for cracks etc.

A test like this could shed some light on the situation, Pm me if anyone would like to do this.

If anyone want's to send me a stock cam and a broken cam Like the op I would be willing to test and share the results.

There is a few other things I can test as well such as a magnaflux for cracks etc.

A test like this could shed some light on the situation, Pm me if anyone would like to do this.

#198

Newbie

Join Date: Jun 2007

Location: Christchurch, NZ

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

Cam info

Belt Harmonics are just and easy way out... it would be hard to measure that....

So again I ask where are the random harmonics coming from?

Mivic map... thats crap too. I happen to know Booster9 was on a completely stock Mivic map, and TNT1106 was on a mild tuned mivic map that is based on a map FP likes to use with their cams (FP never had a problem or failure on their cams even with a more aggressive MIVIC map then TNT had)

To address Kelfords email on the cores... the FP (Comp Cams Core) is very different from the Kelford GSC COSI core. The FP core looks noticeably better finished, the HEX on it is much more defined, there is no grinding of the part line as seen on the kelford either.

Its a simple fix, just a different carbide bit in their CNC lathe, really they dont even have to change the code, sway out sharp edge tool with radius tool....

I am going to try to find time to F.E.A. Kelford, FP, and Stock cams this week at work to see what effect the differences in the groves make.....

Firstly belt harmonics..?

Have you ever watched a timing belt when the engine is on the dyno under acceleration and deceleration? Belt harmonics definatly have a part to play in this, how to measure them and minimise them is near impossible, finding a way to strengthen parts to help protect from their effects is possible.

Mivec map..?, maybe that is crap, but as mentioned I am not an experianced tuner but know my way around an engine pretty well and every option needs looking at. How do you know that at a certain rpm belt frequency is not effected by movements in the map?

Cores..? I was probably not clear enough in my e mail. We use both cores and have done for a long time. The one you call the FP or Comp Cams core has been our core since long before those guys even knew what a EVO IX was.

That core has its own set of issues but it is stronger in the front journal area. Motovicity has had our 9-177-C and -D on the Japan core for a while now as we ran out of the other core earlier this year.

Its a simple fix..?

We put a polished radius in the corner of the mivec grooves and the cams we tested still broke with the same amount of force as the non polished radius cams.

we note that sudden impact is how these break, not even pressure. We are still busting cams daily to look at this and we are just making some more equipment to do so so that we have hard numbers on it for comparison.

Is everyone replacing their tensioner? When I had my EVO IV my local Mitsubishi dealer told me it is a use once item and is mandatory to replace when doing a belt. Any official Mitsubishi word on this would be appreciated if anyone has it.

I am not going to get into argument on here and won't answer hundreds of random questions. If there is something you need to know that directly affects you, e mail me.

I am not really a forum reader or contributor, I will however chime in with info that is pertanant to this discussion or to offer correction and clarification if I think I need to do so.

#199

Evolving Member

iTrader: (1)

Join Date: Sep 2006

Location: District 9

Posts: 428

Likes: 0

Received 0 Likes

on

0 Posts

I just surely hope so.

Cool. That's what I'd like to hear.

edit** it should be noted that i am not advertising for FP. i actually run kelford cams in my own car, and liked them so much i've decided to sell them just 2 weeks ago. but now i can't sell them until i find a solution has been implemented by kelford for the mivec intake cam. for evo8's i would still recommend them.

#200

Evolving Member

iTrader: (9)

ktk - "Instead what seems to be happening is that there is a force that is acting on the cam gears as the tension in the timing belt pulls down on them."

is there a way to lower the force by like making the timing belt slightly looser? I installed my GSC S1's yesterday with a help of a co-worker/friend who owns a evo 8 and installed his hks cams himself. when we were working on my 9 cams we zip tied the cam gear along with the belt and tried loosening it and it would loosen somewhat, but not a lot, but on his 8 he was able to loosen it to the desired position.

is there a way to lower the force by like making the timing belt slightly looser? I installed my GSC S1's yesterday with a help of a co-worker/friend who owns a evo 8 and installed his hks cams himself. when we were working on my 9 cams we zip tied the cam gear along with the belt and tried loosening it and it would loosen somewhat, but not a lot, but on his 8 he was able to loosen it to the desired position.

topturtle - "I have a set of S1 in my garage that Kevin swapped out for the S2s. After seeing the pics Kevin posted I dug them up and looked at the grooves. The grooves look very similar to the FP cams."

whew that's a relief. hope that my gsc s1's won't give me any problems. mivec cams getting snapped / broken is more so on the GSC S2's instead of S1's if i'm not mistakened... didn't hear of any S1's breaking/snapping yet.. "knock on wood" but for those who have had their cams snapped maybe it should've been well lubed / greased since a lot of time metal to metal will wear and eventually break w/o it being well lubed/greased and babied for say like 500 - 1000 miles before pounding it since it takes some time to break in the newly installed parts and for it to "learn"??

As for lubing the cams, that is always a good idea, using assembly lube on any moving parts when installing is a must, that said, it is unlikely that the cap breakage issue is related to installation lube problems. The damages due to lack of lubrication tends to look very different and will happen at the bearings or cam lobes.

Once installed be sure to follow the cam manufacturers break in procedure as well.

after the installation i've been hearing a slight ticking / rattling noise at a very low rpm/idle and i'm thinkin that's normal since before i heard a slight ticking / rattling noise when the engine bay shakes a little as if it was about to stall out at low rpm/idle.

https://www.evolutionm.net/forums/ev...r-lifters.html

#201

Just to chime in to everyone. we are running our own series of tests on Greg's GSC camshafts. I will post results up eventually, I can only run tests in the lab on weekends due to time constraints from work. However I will be running every test and scenario possible to check for failure modes including an SEM shot of a fracture area to check for gas pockets in the castings.

I apologize for not introducing myself, I will do this at a later date.

-Danny

I apologize for not introducing myself, I will do this at a later date.

-Danny

#202

Former Sponsor

iTrader: (56)

Join Date: Sep 2004

Location: DFW, TX

Posts: 2,701

Likes: 0

Received 0 Likes

on

0 Posts

Some good points and some clarification needed.

Firstly belt harmonics..?

Have you ever watched a timing belt when the engine is on the dyno under acceleration and deceleration? Belt harmonics definatly have a part to play in this, how to measure them and minimise them is near impossible, finding a way to strengthen parts to help protect from their effects is possible.

Mivec map..?, maybe that is crap, but as mentioned I am not an experianced tuner but know my way around an engine pretty well and every option needs looking at. How do you know that at a certain rpm belt frequency is not effected by movements in the map?

Cores..? I was probably not clear enough in my e mail. We use both cores and have done for a long time. The one you call the FP or Comp Cams core has been our core since long before those guys even knew what a EVO IX was.

That core has its own set of issues but it is stronger in the front journal area. Motovicity has had our 9-177-C and -D on the Japan core for a while now as we ran out of the other core earlier this year.

Its a simple fix..?

We put a polished radius in the corner of the mivec grooves and the cams we tested still broke with the same amount of force as the non polished radius cams.

we note that sudden impact is how these break, not even pressure. We are still busting cams daily to look at this and we are just making some more equipment to do so so that we have hard numbers on it for comparison.

Is everyone replacing their tensioner? When I had my EVO IV my local Mitsubishi dealer told me it is a use once item and is mandatory to replace when doing a belt. Any official Mitsubishi word on this would be appreciated if anyone has it.

I am not going to get into argument on here and won't answer hundreds of random questions. If there is something you need to know that directly affects you, e mail me.

I am not really a forum reader or contributor, I will however chime in with info that is pertanant to this discussion or to offer correction and clarification if I think I need to do so.

Firstly belt harmonics..?

Have you ever watched a timing belt when the engine is on the dyno under acceleration and deceleration? Belt harmonics definatly have a part to play in this, how to measure them and minimise them is near impossible, finding a way to strengthen parts to help protect from their effects is possible.

Mivec map..?, maybe that is crap, but as mentioned I am not an experianced tuner but know my way around an engine pretty well and every option needs looking at. How do you know that at a certain rpm belt frequency is not effected by movements in the map?

Cores..? I was probably not clear enough in my e mail. We use both cores and have done for a long time. The one you call the FP or Comp Cams core has been our core since long before those guys even knew what a EVO IX was.

That core has its own set of issues but it is stronger in the front journal area. Motovicity has had our 9-177-C and -D on the Japan core for a while now as we ran out of the other core earlier this year.

Its a simple fix..?

We put a polished radius in the corner of the mivec grooves and the cams we tested still broke with the same amount of force as the non polished radius cams.

we note that sudden impact is how these break, not even pressure. We are still busting cams daily to look at this and we are just making some more equipment to do so so that we have hard numbers on it for comparison.

Is everyone replacing their tensioner? When I had my EVO IV my local Mitsubishi dealer told me it is a use once item and is mandatory to replace when doing a belt. Any official Mitsubishi word on this would be appreciated if anyone has it.

I am not going to get into argument on here and won't answer hundreds of random questions. If there is something you need to know that directly affects you, e mail me.

I am not really a forum reader or contributor, I will however chime in with info that is pertanant to this discussion or to offer correction and clarification if I think I need to do so.

its been pointed out that it takes tremendous force to break the cam with a single impact force. GSC apparently hit it with a sledge hammer to proove the strength of the cam.

however, in almost every one of these cases the break wasn't immediate. it was after months and thousands of miles. i would put much more thought into metal fatigue failures. maybe belt harmonics are weakening the cam over time. and your safety factors in the cam design are not great enough. there is obviously nothing wrong with your core that FP uses in the MIVEC groove area is there? if that is where the kelford/gsc style core is breaking, beef it up!.

to think that something happens causing an instant stress on the cam enough to break it like that.... which is stronger? the belt tensioner, the belt, the cam? and why doesn't every evo with all different cam types suffer the same fate?

#203

Evolving Member

iTrader: (9)

Join Date: Oct 2006

Location: DFW, Tx

Posts: 437

Likes: 0

Received 0 Likes

on

0 Posts

Some good points and some clarification needed.

Firstly belt harmonics..?

Have you ever watched a timing belt when the engine is on the dyno under acceleration and deceleration? Belt harmonics definatly have a part to play in this, how to measure them and minimise them is near impossible, finding a way to strengthen parts to help protect from their effects is possible.

Firstly belt harmonics..?

Have you ever watched a timing belt when the engine is on the dyno under acceleration and deceleration? Belt harmonics definatly have a part to play in this, how to measure them and minimise them is near impossible, finding a way to strengthen parts to help protect from their effects is possible.

Cores..? I was probably not clear enough in my e mail. We use both cores and have done for a long time. The one you call the FP or Comp Cams core has been our core since long before those guys even knew what a EVO IX was.

That core has its own set of issues but it is stronger in the front journal area. Motovicity has had our 9-177-C and -D on the Japan core for a while now as we ran out of the other core earlier this year.

Its a simple fix..?

We put a polished radius in the corner of the mivec grooves and the cams we tested still broke with the same amount of force as the non polished radius cams.

we note that sudden impact is how these break, not even pressure. We are still busting cams daily to look at this and we are just making some more equipment to do so so that we have hard numbers on it for comparison.

That core has its own set of issues but it is stronger in the front journal area. Motovicity has had our 9-177-C and -D on the Japan core for a while now as we ran out of the other core earlier this year.

Its a simple fix..?

We put a polished radius in the corner of the mivec grooves and the cams we tested still broke with the same amount of force as the non polished radius cams.

we note that sudden impact is how these break, not even pressure. We are still busting cams daily to look at this and we are just making some more equipment to do so so that we have hard numbers on it for comparison.

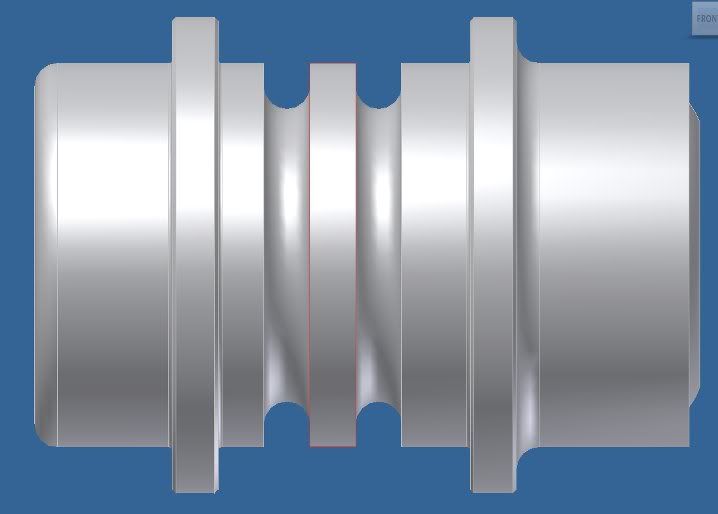

NOT DRAWN TO SCALE... just something quick to get the idea across....

I am not going to get into argument on here and won't answer hundreds of random questions. If there is something you need to know that directly affects you, e mail me.

I am not really a forum reader or contributor, I will however chime in with info that is pertanant to this discussion or to offer correction and clarification if I think I need to do so.

I am not really a forum reader or contributor, I will however chime in with info that is pertanant to this discussion or to offer correction and clarification if I think I need to do so.

#204

Evolved Member

iTrader: (2)

There is a very simple solution here...send in a failed cam or two to a failure analysis lab. Done.

The testing that is being done by the cam manufacturers may be beneficial, but it doesn't represent real world use. From the one picture of the fracture surface that was posted in the other thread (I forgot if it was in this thread), it looked like there was evidence of fatigue. It's hard to go by one picture posted in an internet thread, but there looked to be beach marks, which is a telltale sign of fatigue. Whether it was just the lighting or not, I can't say, since I can't see the cams in person.

Fatigue is a failure due to smaller, repetitive forces over time...forces under what wouldn't normally cause a breakage. A breakage due to a sledge hammer hit is not the same kind of failure and proves nothing if these cams are really failing due to fatigue.

Fatigue can be verified by simple fractography and confirmed by high magnification under an SEM. A qualified lab can do all of this as well as test the alloy composition and look for defects, etc. Not only can a lab verify if this was a fatigue failure or not, they can verify the crack initiation point(s).

I think simply sending a couple of the broken cams to a qualified lab will get the quickest results and real cause of the failures.

The testing that is being done by the cam manufacturers may be beneficial, but it doesn't represent real world use. From the one picture of the fracture surface that was posted in the other thread (I forgot if it was in this thread), it looked like there was evidence of fatigue. It's hard to go by one picture posted in an internet thread, but there looked to be beach marks, which is a telltale sign of fatigue. Whether it was just the lighting or not, I can't say, since I can't see the cams in person.

Fatigue is a failure due to smaller, repetitive forces over time...forces under what wouldn't normally cause a breakage. A breakage due to a sledge hammer hit is not the same kind of failure and proves nothing if these cams are really failing due to fatigue.

Fatigue can be verified by simple fractography and confirmed by high magnification under an SEM. A qualified lab can do all of this as well as test the alloy composition and look for defects, etc. Not only can a lab verify if this was a fatigue failure or not, they can verify the crack initiation point(s).

I think simply sending a couple of the broken cams to a qualified lab will get the quickest results and real cause of the failures.

Last edited by l2r99gst; Mar 16, 2009 at 07:45 AM.

#205

Evolving Member

iTrader: (9)

Join Date: Oct 2006

Location: DFW, Tx

Posts: 437

Likes: 0

Received 0 Likes

on

0 Posts

There is a very simple solution here...send in a failed cam or two to a failure analysis lab. Done.

The testing that is being done by the cam manufacturers may be beneficial, but it doesn't represent real world use. From the one picture of the fracture surface that was posted in the other thread (I forgot if it was in this thread), it looked like there was evidence of fatigue. It's hard to go by one picture posted in an internet thread, but there looked to be beach marks, which is a telltale sign of fatigue. Whether it was just the lighting or not, I can't say, since I can't see the cams in person.

Fatigue is a failure due to smaller, repetitive forces over time...forces under what wouldn't normally cause a breakage. A breakage due to a sledge hammer hit is not the same kind of failure and proves nothing if these cams are really failing due to fatigue.

Fatigue can be verified by simple fractography and confirmed by high magnification under an SEM. A qualified lab can do all of this as well as test the alloy composition and look for defects, etc. Not only can a lab verify if this was a fatigue failure or not, they can verify the crack initiation point(s).

I think simply sending a couple of the broken cams to a qualified lab will get the quickest results and real cause of the failures.

The testing that is being done by the cam manufacturers may be beneficial, but it doesn't represent real world use. From the one picture of the fracture surface that was posted in the other thread (I forgot if it was in this thread), it looked like there was evidence of fatigue. It's hard to go by one picture posted in an internet thread, but there looked to be beach marks, which is a telltale sign of fatigue. Whether it was just the lighting or not, I can't say, since I can't see the cams in person.

Fatigue is a failure due to smaller, repetitive forces over time...forces under what wouldn't normally cause a breakage. A breakage due to a sledge hammer hit is not the same kind of failure and proves nothing if these cams are really failing due to fatigue.

Fatigue can be verified by simple fractography and confirmed by high magnification under an SEM. A qualified lab can do all of this as well as test the alloy composition and look for defects, etc. Not only can a lab verify if this was a fatigue failure or not, they can verify the crack initiation point(s).

I think simply sending a couple of the broken cams to a qualified lab will get the quickest results and real cause of the failures.

They are also set up to do a failure analysis.....

Its in the works here.....

#206

Evolving Member

Join Date: May 2008

Location: Dallas, TX

Posts: 346

Likes: 0

Received 0 Likes

on

0 Posts

My cam is in the lab, when I get results as I have stated before I will post for sure. I don't want any other fellow evo owners to experience this failure or be handled in the manner I have in all this (up to this point).

#207

Evolving Member

I have no doubt that belt harmonics, mivec maps, detonation, balance issues, an many other conditions could have an affect on the cams other than normal operating conditions. However so could spinning the engine to 8k plus, which the cams allow/require us to do. My point is, its admitted that there is a weak spot. The o.e. cams do not seem to have this problem. Even if there are a few isolated cases, how many more thousands of o.e. Cams are out there? So far no fp cams have broke. In the one case I have personal experience with, the cams only came out of the box once to look at, and then were installed by a person that has probably done more 4g63 timing belts than a lot of this site combined, @ arguably the top 4g63 shop in world... As far as fp using the same cores.. The general consensus, is that it is finish machining that needs to be looked at. Its admitted that a larger machined radius would improve it, but then it would move to the next weakest link... I agree, but that's easy to say since that is not done. And who is to say that the next weakest link is too weak for the possible conditions? I'm not trying to argue or point fingers. I'm looking for answers/solutions.

#208

I’ve read the many interesting views and until the facts are confirmed in a lab speculation will continue. In the meantime i will be playing with the idea of introducing a longer hollow bolt with recesses and cross drilled to allow the oil to flow as necessary, while at the same time offer more support to the actual weakened area of the intake cam. That should make a huge difference given the tensile strength of steel being some 100kg per mm square. A 3mm wall thickness bolt will do wonders for adding to it all. Only condition is that the internal thread needs to run right through, about 15mm longer than the current bolt.

In the past i have snapped off rockers from coil bind on the cossie cams and they worked fine for thousands of miles after that at 8500RPM plus on the track. Harmonics is a bugger!

In the past i have snapped off rockers from coil bind on the cossie cams and they worked fine for thousands of miles after that at 8500RPM plus on the track. Harmonics is a bugger!

#209

Evolving Member

iTrader: (20)

Power and Boost will have no affect on failure.

I forgot to ask if these cars all had stock crank pulleys?

Belt harmonics arent an easy way out if you stop and examine the fact that it doesnt absolve them. Its simply a possible explanation of why the failure was caused related to material. It takes a grown man swing a sledge hammer at it to get a similar shear pattern when the cam is at rest.

I forgot to ask if these cars all had stock crank pulleys?

Belt harmonics arent an easy way out if you stop and examine the fact that it doesnt absolve them. Its simply a possible explanation of why the failure was caused related to material. It takes a grown man swing a sledge hammer at it to get a similar shear pattern when the cam is at rest.

both cars have the stock crank pulleys

#210

Evolving Member

iTrader: (10)

Join Date: Nov 2004

Location: Cookeville, TN

Posts: 471

Likes: 0

Received 0 Likes

on

0 Posts

aiyaaah... that doesn't sound good.. ehhh wat's tdc stand for again? srry i'm not familiar w/some of the evo abbreviations :-/ how can u prevent that..? making sure the hash marks line up with the timing belt, making sure the belts also tight enough, torque down the mivec cam bolt, and the correct tensioner position..?? is that one reason why some evo owner's mivec cam gear are sheared? Thanks for the info.

TDC = Top Dead Center