help removing transfer case

#16

Evolving Member

iTrader: (43)

Join Date: Aug 2009

Location: Pine Bush, NY

Posts: 473

Likes: 0

Received 0 Likes

on

0 Posts

I have an OTC slide hammer kit. It came with an adapter that has a hole in it to slide a screw through. Then it threads onto the end of the hammer. You should be able to pick it up at sears. I bought my through the local Matco dealer though. The part in the first row on the left is what you need.

BUT, you can get an 8x1.25 bolt thats VERY long. Thread it in and VERY CAREFULLY tap the head with a chisel and a hammer to slide it out. If you're in a pinch I would try that method.

BUT, you can get an 8x1.25 bolt thats VERY long. Thread it in and VERY CAREFULLY tap the head with a chisel and a hammer to slide it out. If you're in a pinch I would try that method.

Last edited by mayberry; Jan 22, 2010 at 10:02 PM.

#24

Evolved Member

iTrader: (23)

I have an OTC slide hammer kit. It came with an adapter that has a hole in it to slide a screw through. Then it threads onto the end of the hammer. You should be able to pick it up at sears. I bought my through the local Matco dealer though. The part in the first row on the left is what you need.

BUT, you can get an 8x1.25 bolt thats VERY long. Thread it in and VERY CAREFULLY tap the head with a chisel and a hammer to slide it out. If you're in a pinch I would try that method.

BUT, you can get an 8x1.25 bolt thats VERY long. Thread it in and VERY CAREFULLY tap the head with a chisel and a hammer to slide it out. If you're in a pinch I would try that method.

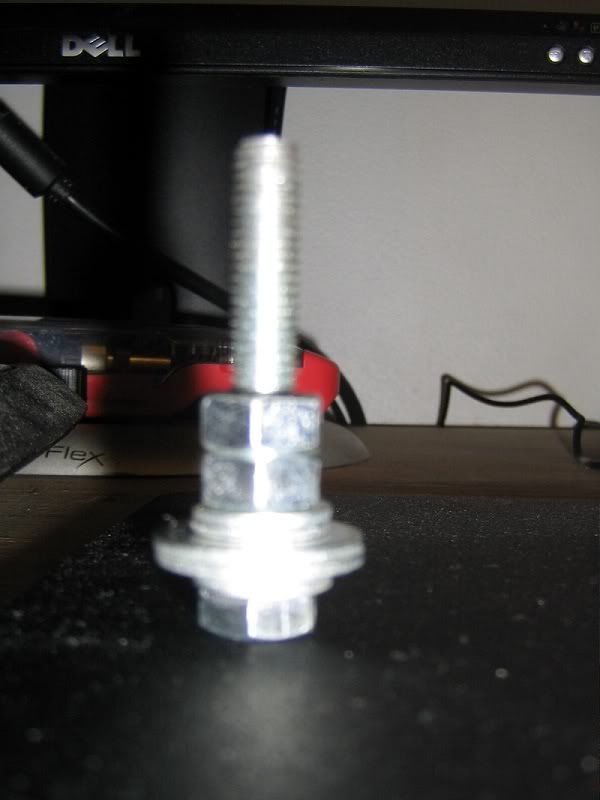

All you need is:

The 8x1.25 bolt with a matching nut

A washer that goes with the bolt

The slide hammer kit from Advanced, not Autozone.

These were the only things I used from the kit.

Depending on what size washers you bought, 1 would work for small ones and 2 would work for big ones. So far, I used 2 because of my washer setup.

This is the bolt I used and how I had it setup with the washers.

Just as is, I put the bolt into the axle on the driver side.

Then, I put the hooks on to the middle piece and the middle piece onto the slide hammer. To make things easier, only use 2 of the 3.

Hook the hooks onto the washer then slide hammer it out! No welding tricks needed and since it's a loaner tool, you can return it back to Advanced to get all your money back same day.

Note: As for putting it back on, you wouldn't need a slide hammer again. A rubber mallet or a dead hammer would work great. Just make sure you don't use a steel hammer or you'll have some problems with chipping.

Another thing on why I used 2 nuts is so that the washers are locked in place and has no chance of moving around.

#25

Newbie

Thread Starter

iTrader: (9)

Join Date: Sep 2009

Location: Miami, Fl

Posts: 88

Likes: 0

Received 0 Likes

on

0 Posts

I got it off. I found a bolt that threaded in and i made it work. Now i need to remove the tranny from the block. What is the procedure for that?? Thanks again for all the help!

#26

Evolved Member

iTrader: (4)

Well if you are doing it with the engine still in, then the process goes something like this.... remove the front/rear engine mounts and of course the tranny engine mount, taking some if not all of the engine mount studs out of the tranny for clearance. Disconnect all the peripherals like the clutch slave cylinder and shifter linkage, undo the throwout bearing clip, by holding the clutch fork to to one of the sides (can't remember) and prying with a flathead. Pull the 6 or so bolts that connect the tranny to the engine and use a pry bar to start sliding it off and down, while swearing the whole way because it is a serious PITA. Of course getting it on that way is even worse.

I chose to pull my whole engine, but to me that is much easier than wrestling the tranny the way you intend to. Of course it takes a lot longer, because you have a lot more to disconnect, but to each their own.

I think your best bet doing it with the engine still in is using a hoist to stabilize the tranny while moving it around with a jack, human power.

I chose to pull my whole engine, but to me that is much easier than wrestling the tranny the way you intend to. Of course it takes a lot longer, because you have a lot more to disconnect, but to each their own.

I think your best bet doing it with the engine still in is using a hoist to stabilize the tranny while moving it around with a jack, human power.

Last edited by fre; Jan 24, 2010 at 08:11 AM.

#27

Evolving Member

iTrader: (3)

the hardest thing about droping and puting back the transmision is clearing the subframe. I actually read one write up that they droped that as well but that requires disconecting the steering rack and power steering lines etc. It was just plain difficult you need to go at it with the propper angles

Thread

Thread Starter

Forum

Replies

Last Post

FS[South]: 2005 acd transfer case

mbnworld

For Sale/WTB - Engine / Drivetrain / Power

0

Jun 24, 2016 02:22 PM

theblue

Evo How To Requests / Questions / Tips

4

Jul 28, 2008 01:04 PM

J-ROC

Evo How To Requests / Questions / Tips

21

Sep 25, 2007 09:32 PM