Homemade "Boost-A-Pump", has anyone made one!?

#1

Hello,

I'm looking at making a homemade "boost-a-pump" system, to run my fuel pump on 16 or 18volts so i dont have to replace my 255lph walbro pump for my power goals.

It will be high/low switched either by boost pressure or by my ecu (Link G4 xtreme).

Do we have any resident circuit designers that could help me out with the component selection and design?

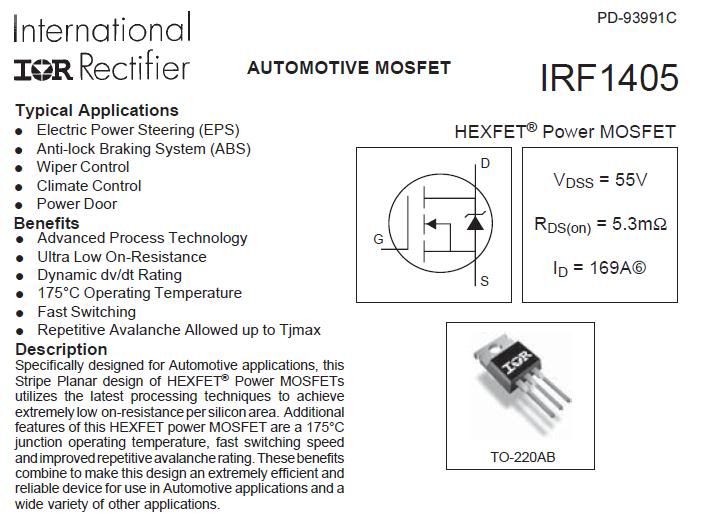

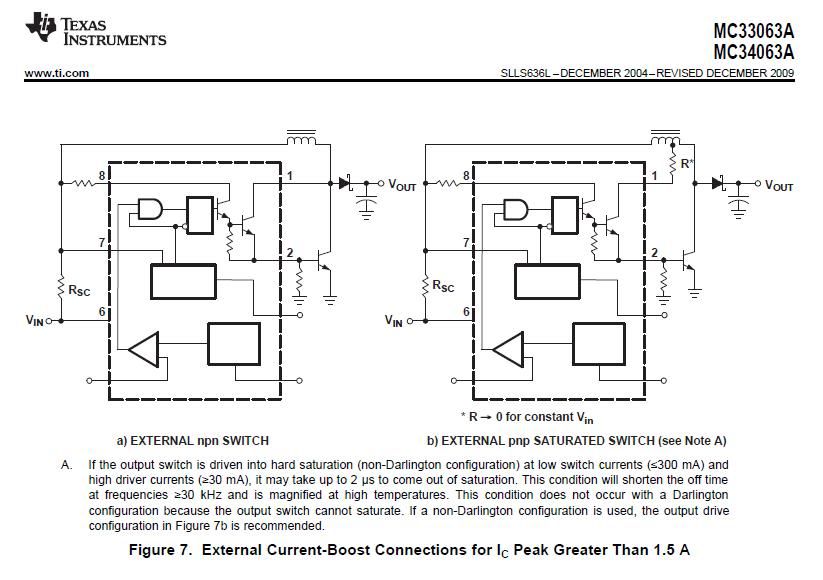

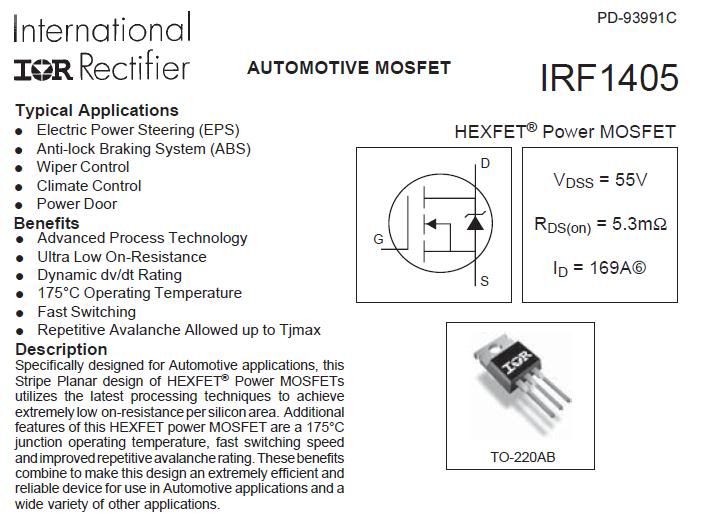

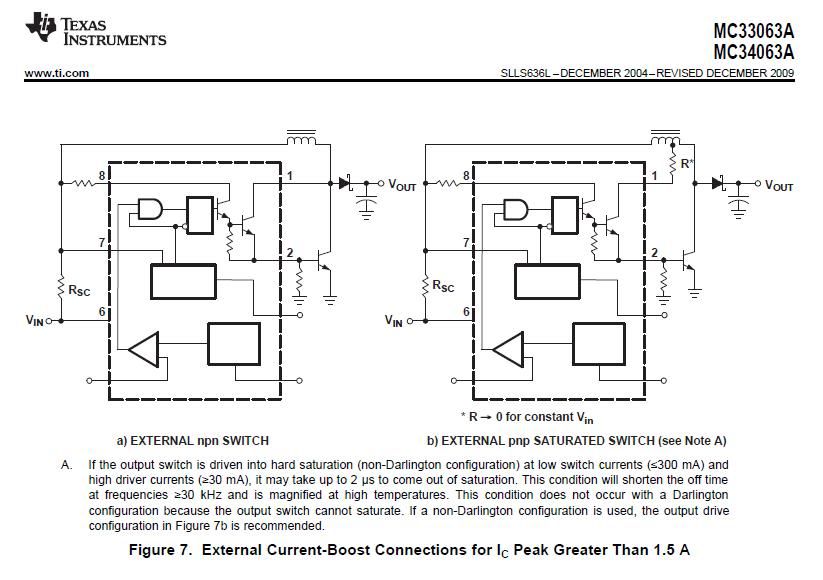

I already have an IC sorted. I'm going to use a basic Step-up step mode power supply, feeding into a Mosfet to control the high current load that will be needed. Full load @ 18v should be about 15Amps, but i want to build it for 20A.

I know i can buy these off the shelf for about $250USD, but i could probably build one for $30USD. I work in electronics for the living, so i can build it at work.

I just dont have the circuit construction experience.

Any help would be good!

Cheers, Mike

I'm looking at making a homemade "boost-a-pump" system, to run my fuel pump on 16 or 18volts so i dont have to replace my 255lph walbro pump for my power goals.

It will be high/low switched either by boost pressure or by my ecu (Link G4 xtreme).

Do we have any resident circuit designers that could help me out with the component selection and design?

I already have an IC sorted. I'm going to use a basic Step-up step mode power supply, feeding into a Mosfet to control the high current load that will be needed. Full load @ 18v should be about 15Amps, but i want to build it for 20A.

I know i can buy these off the shelf for about $250USD, but i could probably build one for $30USD. I work in electronics for the living, so i can build it at work.

I just dont have the circuit construction experience.

Any help would be good!

Cheers, Mike

#3

http://www.kennebell.net/accessories...boostapump.htm

people use them to great success.

i do electronics for a living so $400NZD to me for a powersupply is not an option when i can just build my own for a 1/10 the price

people use them to great success.

i do electronics for a living so $400NZD to me for a powersupply is not an option when i can just build my own for a 1/10 the price

#5

i was going to build one at work. i had a friend that did a degree in electronics etc, but he moved workplace so i haven't found the time to pick his brain about it yet.

It's all good on paper but i just need to do a prototype i guess and see how it goes!

It's all good on paper but i just need to do a prototype i guess and see how it goes!

#6

I have the bell boost a pump. It may be easy to make circuit to boost the volts to 18v. But maintaining it at 18v even when battery is at 10v is the complex part.

i choose this because i didnt want to chop up fuel lines to add a second pump. I was disappointed with results boosting the walbro 255. the flow only increased by one point. A/F went from 11/1 to 10/1 with the boost a pump. twin pumps will drop a/f 2-3 points.

adding voltage has no ill effect on motors. they run more efficient on less amps given same load.

i choose this because i didnt want to chop up fuel lines to add a second pump. I was disappointed with results boosting the walbro 255. the flow only increased by one point. A/F went from 11/1 to 10/1 with the boost a pump. twin pumps will drop a/f 2-3 points.

adding voltage has no ill effect on motors. they run more efficient on less amps given same load.

#7

I have the bell boost a pump. It may be easy to make circuit to boost the volts to 18v. But maintaining it at 18v even when battery is at 10v is the complex part.

i choose this because i didnt want to chop up fuel lines to add a second pump. I was disappointed with results boosting the walbro 255. the flow only increased by one point. A/F went from 11/1 to 10/1 with the boost a pump. twin pumps will drop a/f 2-3 points.

adding voltage has no ill effect on motors. they run more efficient on less amps given same load.

i choose this because i didnt want to chop up fuel lines to add a second pump. I was disappointed with results boosting the walbro 255. the flow only increased by one point. A/F went from 11/1 to 10/1 with the boost a pump. twin pumps will drop a/f 2-3 points.

adding voltage has no ill effect on motors. they run more efficient on less amps given same load.

as you should know this, you'll only get a change AFR when the pump is struggling in the first place. So saying the AFR change was less than desired, is dependant on the overall fuel flow required. AFR will only change is the fuel pressure changes (if IDC stays the same).

running a fuel pump at a higher voltage will just cause it to spin faster. so it will flow more fuel at any given pressure.

I think your last statement is a little off. The pump is a set resistance, if you add extra voltage, it will draw more current. Thats why the boostApump turns on at a set boost pressure, so that the pump isnt working harder where the extra fuel flow isn't needed

Cheers, Mike

Last edited by RSMike; May 22, 2010 at 05:51 PM.

Trending Topics

#8

maybe you misunderstood my last statement. I was referring to joules law. P=VI

in this case P=Power= amount of energy needed to flow fuel. V=volts. I= current.

500hp requires a set fuel flow. That does not change. If P is constant when you raise V from 13 to 18 then less I (current) will be needed. Thus the pump becomes more efficient and is not working as hard.

The boost a pump maintains 17.5V even if your alternator dies. Its a nice feature. The factory voltage at pump varies with ancillaries that are on. and goes way south when alternator dies.

There are people making circuits for fuel injectors that raise volts to 18-30V range. With fantastic results. I suspect the next tool to pop up will be a box that does both.

in this case P=Power= amount of energy needed to flow fuel. V=volts. I= current.

500hp requires a set fuel flow. That does not change. If P is constant when you raise V from 13 to 18 then less I (current) will be needed. Thus the pump becomes more efficient and is not working as hard.

The boost a pump maintains 17.5V even if your alternator dies. Its a nice feature. The factory voltage at pump varies with ancillaries that are on. and goes way south when alternator dies.

There are people making circuits for fuel injectors that raise volts to 18-30V range. With fantastic results. I suspect the next tool to pop up will be a box that does both.

#9

500hp requires a set fuel flow. That does not change. If P is constant when you raise V from 13 to 18 then less I (current) will be needed. Thus the pump becomes more efficient and is not working as hard.

i understand what you are saying here, but i dont really think it's relevant.

The boost a pump maintains 17.5V even if your alternator dies. Its a nice feature. The factory voltage at pump varies with ancillaries that are on. and goes way south when alternator dies.

There are people making circuits for fuel injectors that raise volts to 18-30V range. With fantastic results. I suspect the next tool to pop up will be a box that does both.

#10

#11

here's what i was thinking

using the high current mosfet for the output, it needs to be able to handle the peak current flow, which for my scenario is about 100amps.

i just need help with the other components and someone to bounce ideas off

using the high current mosfet for the output, it needs to be able to handle the peak current flow, which for my scenario is about 100amps.

i just need help with the other components and someone to bounce ideas off

Thread

Thread Starter

Forum

Replies

Last Post

mrfred

Evo Engine / Turbo / Drivetrain

383

Jul 16, 2024 10:29 PM

Terror Rising

Project Cars / Build Threads

179

Jul 28, 2019 07:20 PM

Rik84

Project Cars / Build Threads

14

Nov 23, 2013 10:56 AM