Forge 18 psi WGA ascillation

#1

Evolved Member

Thread Starter

iTrader: (14)

Join Date: Aug 2009

Location: London, Ontario

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

Forge 18 psi WGA oscillation

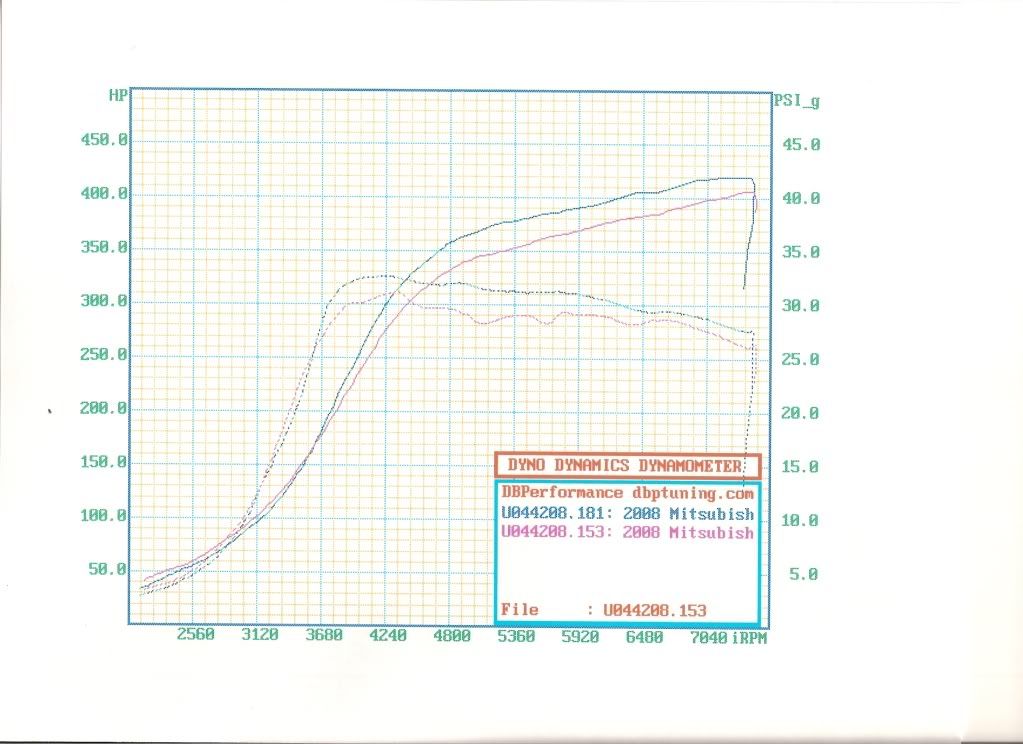

Hello, I recently installed the Forge 18psi unit on my 9 turbo. It has been preloaded 4 complete turns. Currently, the boost spikes to about 27.5, drops 2-3 psi quickly and comes back up.... oscillates slightly to redline where its sitting at 24-25 psi. The peak and the taper im happy with, im just not happy with the oscillation.

Just wondering if this is normal, or do I have to preload it more? Using the Forge MBC as well, and BLT was good. Just looking for some opinions, it would be nice to smooth out the load.

Bren

Just wondering if this is normal, or do I have to preload it more? Using the Forge MBC as well, and BLT was good. Just looking for some opinions, it would be nice to smooth out the load.

Bren

Last edited by brenner; Aug 17, 2010 at 12:16 PM.

#4

Evolved Member

Thread Starter

iTrader: (14)

Join Date: Aug 2009

Location: London, Ontario

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

no im not sure. I went to the stiffer spring as the soft one wouldnt reach the boost levels i wanted. I can try swapping back I guess

Edit, didnt do this previously on my softer spring, would hit 26 taper to 21 without the fluctuation, but also on the stock wga. Changed both the spring and the WGA this week

Edit, didnt do this previously on my softer spring, would hit 26 taper to 21 without the fluctuation, but also on the stock wga. Changed both the spring and the WGA this week

Last edited by brenner; Aug 17, 2010 at 02:18 PM.

#5

Evolved Member

iTrader: (1)

Join Date: Mar 2005

Location: Mesoamerica/ SF Bay Area

Posts: 7,905

Likes: 0

Received 5 Likes

on

5 Posts

Do you mean that 1st you adjusted it to where it slides freely on and off the flapper valve's pivot arm? And that once you had it so set(base setting) you went on to turn the turnbuckle on the end of the actuator rod inward four complete 360* revolutions? I am just trying to clear a doubt in my mind.

#6

Evolved Member

Thread Starter

iTrader: (14)

Join Date: Aug 2009

Location: London, Ontario

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

4 complete rotations from sliding on the flapper freely. I assume thats what you meant from "base setting"

As I read it, that was an adequate amount. Do you think it requires more adjustment?

As I read it, that was an adequate amount. Do you think it requires more adjustment?

#7

Evolved Member

iTrader: (1)

Join Date: Mar 2005

Location: Mesoamerica/ SF Bay Area

Posts: 7,905

Likes: 0

Received 5 Likes

on

5 Posts

Just off the top of my head after reading your opening post and taking into consideration that you are running 28# peak boost. I'd say that four turns is not quite enough. Four turns gives you about 15# of spring pressure.

Since you are running 28# peak, then I would say that you should be running about 22-24 PSI of spring pressure.

Since you are running 28# peak, then I would say that you should be running about 22-24 PSI of spring pressure.

Trending Topics

#9

Evolved Member

iTrader: (1)

Join Date: Mar 2005

Location: Mesoamerica/ SF Bay Area

Posts: 7,905

Likes: 0

Received 5 Likes

on

5 Posts

The cleanest, most rock solid way to set your spring pressure, IMO, is to disconnect your MBC and run a vacuum hose directly from the WGA to the compressor oulet discharge tube's nipple and adjust spring pressure by rotating the turnbuckle until you get it to 22-24#. Once this is set then reconnect your MBC and via the MBC raise the boost up the last 3-4 to your target boost.

#11

Evolved Member

Thread Starter

iTrader: (14)

Join Date: Aug 2009

Location: London, Ontario

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

The cleanest, most rock solid way to set your spring pressure, IMO, is to disconnect your MBC and run a vacuum hose directly from the WGA to the compressor oulet discharge tube's nipple and adjust spring pressure by rotating the turnbuckle until you get it to 22-24#. Once this is set then reconnect your MBC and via the MBC raise the boost up the last 3-4 to your target boost.

That was my next step... and it will also rule out the WGA as the "fluctuator"

Ill do that tomorrow, and if its still ****ed, Ill try something else. Thanks for the tips.

#12

Evolved Member

iTrader: (1)

Join Date: Mar 2005

Location: Mesoamerica/ SF Bay Area

Posts: 7,905

Likes: 0

Received 5 Likes

on

5 Posts

MBC all the way down, does not mean knob turned all the way in does it? All the way out would be lowest boost setting where as all the way in kinda means highest boost setting.

I just want to be speaking the same lingo so as not to confuse you. Sorry.

I have run the same actuator as you. and I am pretty familiar with it by now. I had to chop a few of the threads off the end of mine to get it to tighten down to the spring pressure that I desire.

I just want to be speaking the same lingo so as not to confuse you. Sorry.

I have run the same actuator as you. and I am pretty familiar with it by now. I had to chop a few of the threads off the end of mine to get it to tighten down to the spring pressure that I desire.

#13

Evolved Member

Thread Starter

iTrader: (14)

Join Date: Aug 2009

Location: London, Ontario

Posts: 526

Likes: 0

Received 0 Likes

on

0 Posts

MBC all the way down, does not mean knob turned all the way in does it? All the way out would be lowest boost setting where as all the way in kinda means highest boost setting.

I just want to be speaking the same lingo so as not to confuse you. Sorry.

I run the same actuator as you. and I am pretty familiar with it by now. I had to chop a few of the threads off the end of mine to get it to tighten down to the spring pressure that I desire.

I just want to be speaking the same lingo so as not to confuse you. Sorry.

I run the same actuator as you. and I am pretty familiar with it by now. I had to chop a few of the threads off the end of mine to get it to tighten down to the spring pressure that I desire.

by down i mean turned to the "lowest boost setting"... on the Forge unos its counterclockwise till it stops.

did you ever have boost wave like I am experiencing when dialing in your WGA?

#14

Evolved Member

iTrader: (1)

Join Date: Mar 2005

Location: Mesoamerica/ SF Bay Area

Posts: 7,905

Likes: 0

Received 5 Likes

on

5 Posts

I like running as much spring pressure as possible for various reasons. I have found that I can get MBC's to control boost more precisely if WG spring pressure is on the high side. This way the operant range of adjustability for the MBC is reduced.

For example: If my peakboost is set for 25# then I like WG spring pressure to be about 3# under that peak level, or 21-22# of spring pressure. That way the MBC only deals with 3#'s of adjustability.

For example: If my peakboost is set for 25# then I like WG spring pressure to be about 3# under that peak level, or 21-22# of spring pressure. That way the MBC only deals with 3#'s of adjustability.