New BW EFR Turbo Thread

#3166

Absolutely there is additional boundary wall effects. That's largely why the recommendation in the SAE papers is 60% and not 50% for spool and 90% not 100% for power. That is the empirical data results shown in a real world testing. That is the impact of the divider.

As for the chart, I can't comment as I have no idea what either of you have and different cars/motors/setups/tunes will behave very differently.

As for the chart, I can't comment as I have no idea what either of you have and different cars/motors/setups/tunes will behave very differently.

#3167

You aren't talking about the same paper I am. It wasn't on a wankle motor and it wasn't at 8psi. I believe I have 2-3 different papers on this subject actually but the main one...If I get a minute on the home computer I'll find the paper number.

Yes though, above about 5000RPM, there is so much pulse energy it makes little difference on response.

Yes though, above about 5000RPM, there is so much pulse energy it makes little difference on response.

#3168

You aren't talking about the same paper I am. It wasn't on a wankle motor and it wasn't at 8psi. I believe I have 2-3 different papers on this subject actually but the main one...If I get a minute on the home computer I'll find the paper number.

Yes though, above about 5000RPM, there is so much pulse energy it makes little difference on response.

Yes though, above about 5000RPM, there is so much pulse energy it makes little difference on response.

#3169

Its probably more like 3600rpm's as 116+ pulses per second under load is enough streaming to make transient response b/w the two very similar as evidenced by the torque graph. I was referring to the 4-5000rpm powerband afterwards that is a wash in terms of transients and with the open scroll with equal or similar A/R's having superior flow.

#3170

Pulses per second means nothing. Pay attention to the timeframe between pulses. It is the interruptions in flow that hurt response. For this, of course you have to look at RPM but also valve duration and overlap. Judging by dyno charts i've seen of Evo 10's, this probably happens somehwere around 4200-4500 rpm. For 9's, add 500 rpm.

#3171

https://www.facebook.com/officialcbrdspeedfactory

did you guys see this from CBRD facebook? excited to see some 8/9 results from their new kit.

did you guys see this from CBRD facebook? excited to see some 8/9 results from their new kit.

#3172

New BW EFR Turbo Thread

Originally Posted by hispanicpanic

Pulses per second means nothing. Pay attention to the timeframe between pulses. It is the interruptions in flow that hurt response. For this, of course you have to look at RPM but also valve duration and overlap. Judging by dyno charts i've seen of Evo 10's, this probably happens somehwere around 4200-4500 rpm. For 9's, add 500 rpm.

#3173

Its probably more like 3600rpm's as 116+ pulses per second under load is enough streaming to make transient response b/w the two very similar as evidenced by the torque graph. I was referring to the 4-5000rpm powerband afterwards that is a wash in terms of transients and with the open scroll with equal or similar A/R's having superior flow.

Even with a small turbo (boost threshold of like 2500 RPM), the time to boost difference didn't nullify until around 5000RPM with just the difference between ball bearing and journal bearing. From my experience, the difference in response between TS and SS is significantly more of a difference than BB and JB.

#3175

Turbine housing is tight to the block, its almost like it was meant to go there  . I don't see a mount for the turbo, are the 8/9 kits also getting pipe manifolds instead of tube?

. I don't see a mount for the turbo, are the 8/9 kits also getting pipe manifolds instead of tube?

. I don't see a mount for the turbo, are the 8/9 kits also getting pipe manifolds instead of tube?

. I don't see a mount for the turbo, are the 8/9 kits also getting pipe manifolds instead of tube?

#3177

LOL!

we used to supply a bolt for the front balance shaft phase check hole that had a lower profile head for more clearance lol!

this is pipe-

we still do our tube LMP kit- but not very often- the pipe allows us to eliminate the bracket-

cb

#3178

#3179

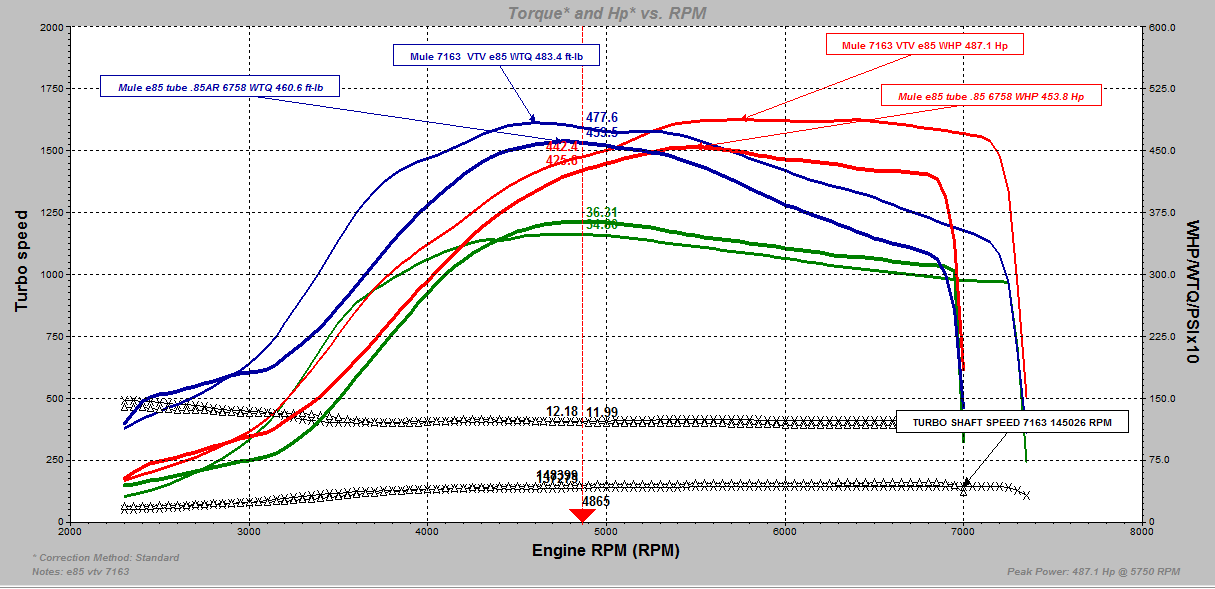

Be sure to note the boost pressures between the two turbos too, not completely apples to apples if gawking at overall, the 7163 was peaking at about 34psi, the 6758 at 36psi. Both out of their sweet spots. On better VE engines where you can keep the pressure ratios lower, they make loads more power(we make 550whp on the Audi TTRS 2.5TFSI with the same style manifold, dyno, fuel, but can keep it at ~24-25psi)

Look at how the torque and HP ramps on teh 7163 on the onset. It isn't a standard ramp and hold, you can see the A/R being varied and the engine responding accordingly. It does ramp a lot faster with the smaller A/R, aka transient is unreal. Imagine how it feels on the street if you have ever been in a 6758 car

I can dig up data showing the 7163 held at .52A/R to redline, but it isn't pretty. If it made 430whp, I'd be surprised. You can kind of guess if you look at the 7163 line as to what the hp and torque would look like if it continued.

I can dig up data showing the 7163 held at .52A/R to redline, but it isn't pretty. If it made 430whp, I'd be surprised. You can kind of guess if you look at the 7163 line as to what the hp and torque would look like if it continued.

Last edited by URQaudiguy; Jul 17, 2015 at 10:21 AM.

#3180

Others vendors have proven, 1.2:1 exhaust back pressure to MAP is a very acceptable range for a street setup. Sure, it won't set pumpgas HP records, but it will have a fat *** powerband that will be a lot more fun to drive then the 1:1 setup. Now sure, if you want to run 30+ psi on 91, yeah 1:1 is pretty useful and will definitely let you turn up the boost.

There are a couple SAE papers on this topic but I'll summarize. Consider firstly that you are talking pulse flow. On a 4 cylinder engine, you really don't have (much) more then 1 pulse trying to go through the turbo at a given time. By going TS with the same A/R, you effectively cut your flow area in half for each pulse. Your 0.80A/R TS effectively has the same flow area as a 0.40 A/R openscroll with regards to that single pulse.

Now consider the open scroll and you'll notice I said "don't have (much) more then 1 pulse trying to go through the turbo at a given time." When you size an openscroll housing, you are sizing so that when you do get overlap between pulses, you have enough flow area to not choke out the pulse. Essentially, you have more flow area then you really need if those pulses were coming in with zero overlap.

So....basic suggestions from SAE peer reviewed technical papers: A TS A/R housing will spool about like an OS housing that is 60% of it's size. Thus, that 0.80A/R TS is about the same for spool as a 0.48 A/R OS.

Power wise however, on a 4 cylinder with proper phasing, the TS performs at roughly 90% of the A/R so that same 0.80 A/R TS is roughly the same as a 0.72A/R OS housing, PROVIDED you are not getting pulse overlap. Basically, at the RPM range where the cam and exhaust manifold are working together, you can get away with a fairly small A/R housing and match the peak torque of an OS housing of nearly the same size. Above that RPM point though, you get pulse stack up and it starts to choke the motor.

This is where that 60% spool figure come into play, take an OS housing that meets your spool needs and multiply it by 1/60%. If 0.72 A/R OS scroll is your ideal, then you need a 1.2 A/R TS housing to match the spool of the OS. OK...so now you have a huge *** housing and response suffers?

Not really...each pair of cylinders at low RPM (where there is no pulse overlap) is seeing only half that housing. The setup will have the transient response of ~0.60 A/R housing...

So...1.2 A/R TS spools like 0.72 A/R and has the transient response of a 0.6 A/R housing all while having the power potential of a 1.08 A/R OS housing. Now...I fully admit, there are boundary effects to take into account as well as thermal transients that definitely skew this. Also how the bigger A/R housing interacts with the wheel is different and typically, you see lower peak turbine efficiency with a larger A/R housing. Typically though, that 1.08A/R power potentially is really larger than what you need as it takes the turbo beyond the VE capabilities of the engine. So you drop down to something like 1.05 A/R, get the power of a 0.95 A/R OS, the spool of a 0.63 A/R and the transient response of a 0.52 A/R housing.

Also...there is something people seem to be ignoring. A/R is a ratio. Two housings can have the same A/R but be VERY different on flow area. This was the point of T3 and T4 as originally, the T4 had a bigger "R" then T3 so the same A/R meant it had a bigger area then the T3 housing. This has kind of gone out the window in the last few years though. The new Garrett T3 TS housings for example use a larger "R" then the "International T3" divided housings used in the past. It appears Garrett basically stuffed the biggest flow area possible that matched up to the T3 divided inlet size. As such, despite having the T3 name, they flow considerably better than older T3 divided housings. Not quiet T4 size...but definitely bigger.

There are a couple SAE papers on this topic but I'll summarize. Consider firstly that you are talking pulse flow. On a 4 cylinder engine, you really don't have (much) more then 1 pulse trying to go through the turbo at a given time. By going TS with the same A/R, you effectively cut your flow area in half for each pulse. Your 0.80A/R TS effectively has the same flow area as a 0.40 A/R openscroll with regards to that single pulse.

Now consider the open scroll and you'll notice I said "don't have (much) more then 1 pulse trying to go through the turbo at a given time." When you size an openscroll housing, you are sizing so that when you do get overlap between pulses, you have enough flow area to not choke out the pulse. Essentially, you have more flow area then you really need if those pulses were coming in with zero overlap.

So....basic suggestions from SAE peer reviewed technical papers: A TS A/R housing will spool about like an OS housing that is 60% of it's size. Thus, that 0.80A/R TS is about the same for spool as a 0.48 A/R OS.

Power wise however, on a 4 cylinder with proper phasing, the TS performs at roughly 90% of the A/R so that same 0.80 A/R TS is roughly the same as a 0.72A/R OS housing, PROVIDED you are not getting pulse overlap. Basically, at the RPM range where the cam and exhaust manifold are working together, you can get away with a fairly small A/R housing and match the peak torque of an OS housing of nearly the same size. Above that RPM point though, you get pulse stack up and it starts to choke the motor.

This is where that 60% spool figure come into play, take an OS housing that meets your spool needs and multiply it by 1/60%. If 0.72 A/R OS scroll is your ideal, then you need a 1.2 A/R TS housing to match the spool of the OS. OK...so now you have a huge *** housing and response suffers?

Not really...each pair of cylinders at low RPM (where there is no pulse overlap) is seeing only half that housing. The setup will have the transient response of ~0.60 A/R housing...

So...1.2 A/R TS spools like 0.72 A/R and has the transient response of a 0.6 A/R housing all while having the power potential of a 1.08 A/R OS housing. Now...I fully admit, there are boundary effects to take into account as well as thermal transients that definitely skew this. Also how the bigger A/R housing interacts with the wheel is different and typically, you see lower peak turbine efficiency with a larger A/R housing. Typically though, that 1.08A/R power potentially is really larger than what you need as it takes the turbo beyond the VE capabilities of the engine. So you drop down to something like 1.05 A/R, get the power of a 0.95 A/R OS, the spool of a 0.63 A/R and the transient response of a 0.52 A/R housing.

Also...there is something people seem to be ignoring. A/R is a ratio. Two housings can have the same A/R but be VERY different on flow area. This was the point of T3 and T4 as originally, the T4 had a bigger "R" then T3 so the same A/R meant it had a bigger area then the T3 housing. This has kind of gone out the window in the last few years though. The new Garrett T3 TS housings for example use a larger "R" then the "International T3" divided housings used in the past. It appears Garrett basically stuffed the biggest flow area possible that matched up to the T3 divided inlet size. As such, despite having the T3 name, they flow considerably better than older T3 divided housings. Not quiet T4 size...but definitely bigger.

And like you commented, I don't do a ton of 4g63 so I can't comment, but yes, these old 4v 5 cylinders are not fond of ratios much above 1:1 on pump 91 without meth. If it has gobs of compressor, onset and torque peak can ride a little higher, but up top for peak power 1:1 is keeping it real.

Great technical information in here.