Crankshaft Stresses 101

#16

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

once you have w, then w = v/r

easy way to get your vector value (V)....

now that you have the V, you have to calculate your acceleration and deceleration of the rod/piston assembly as it goes up and down.

ill have to think some more on how to do that...

i think its 200 level statics tho.

haha

easy way to get your vector value (V)....

now that you have the V, you have to calculate your acceleration and deceleration of the rod/piston assembly as it goes up and down.

ill have to think some more on how to do that...

i think its 200 level statics tho.

haha

Let's step this up to 102 first. Hahaha!!

#18

yep.

i would suggest calculate forces on the assembly at a constant state... say 6000 rpms with no other forces (as in no combustion). you can add that later.

so... force on the rod/piston at TDC and BDC = 0

force on the rod/piston is greatest at highest acceleration which is at 90deg past bdc/tdc because this is where vector force of the crank is perpendicular to the crank.

i would suggest calculate forces on the assembly at a constant state... say 6000 rpms with no other forces (as in no combustion). you can add that later.

so... force on the rod/piston at TDC and BDC = 0

force on the rod/piston is greatest at highest acceleration which is at 90deg past bdc/tdc because this is where vector force of the crank is perpendicular to the crank.

Last edited by hutch959; May 15, 2018 at 06:12 PM.

The following users liked this post:

2006EvoIXer (May 15, 2018)

#19

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

yep.

i would suggest calculate forces on the assembly at a constant state... say 6000 rpms with no other forces (as in no combustion). you can add that later.

so... force on the rod/piston at TDC and BDC = 0

force on the rod/piston is greatest at highest acceleration which is at 90deg past bdc/tdc because this is where vector force of the crank is perpendicular to the crank.

i would suggest calculate forces on the assembly at a constant state... say 6000 rpms with no other forces (as in no combustion). you can add that later.

so... force on the rod/piston at TDC and BDC = 0

force on the rod/piston is greatest at highest acceleration which is at 90deg past bdc/tdc because this is where vector force of the crank is perpendicular to the crank.

Let me figure out which parts I'm going to build with and I'll run through some basic calculations

#20

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

2winscroll brought up a good point in another thread. I need to account for rotational acceleration/deceleration on pistons. For 94mm crank, there is a 5% increase in speed as pistons reach mid point.

Update: theoretical max piston speed already takes into account the crank angles.

Update: theoretical max piston speed already takes into account the crank angles.

Last edited by 2006EvoIXer; Jun 1, 2018 at 11:45 PM.

#25

Originally Posted by 2006EvoIXer

2winscroll brought up a good point in another thread. I need to account for rotational acceleration/deceleration on pistons. For 94mm crank, there is a 5% increase in speed as pistons reach mid point.

That drops my rev limit for 94mm crank from 8,298 rpm to 7,883 rpm. Well that sucks!!

With 153mm rods, rev limit increases to 7,900rpm. Is this extra 17rpm worth $500?

That drops my rev limit for 94mm crank from 8,298 rpm to 7,883 rpm. Well that sucks!!

With 153mm rods, rev limit increases to 7,900rpm. Is this extra 17rpm worth $500?

#29

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

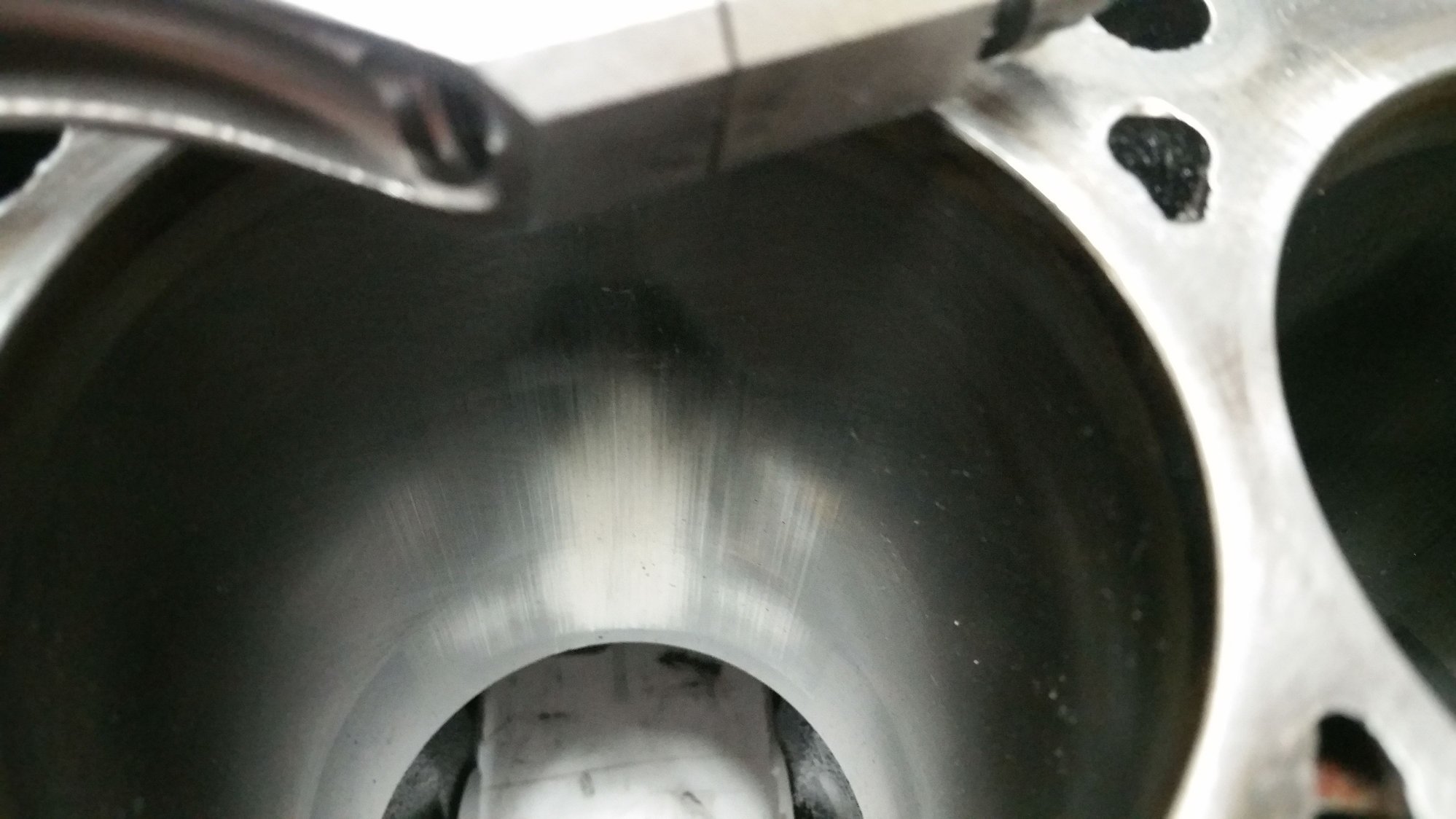

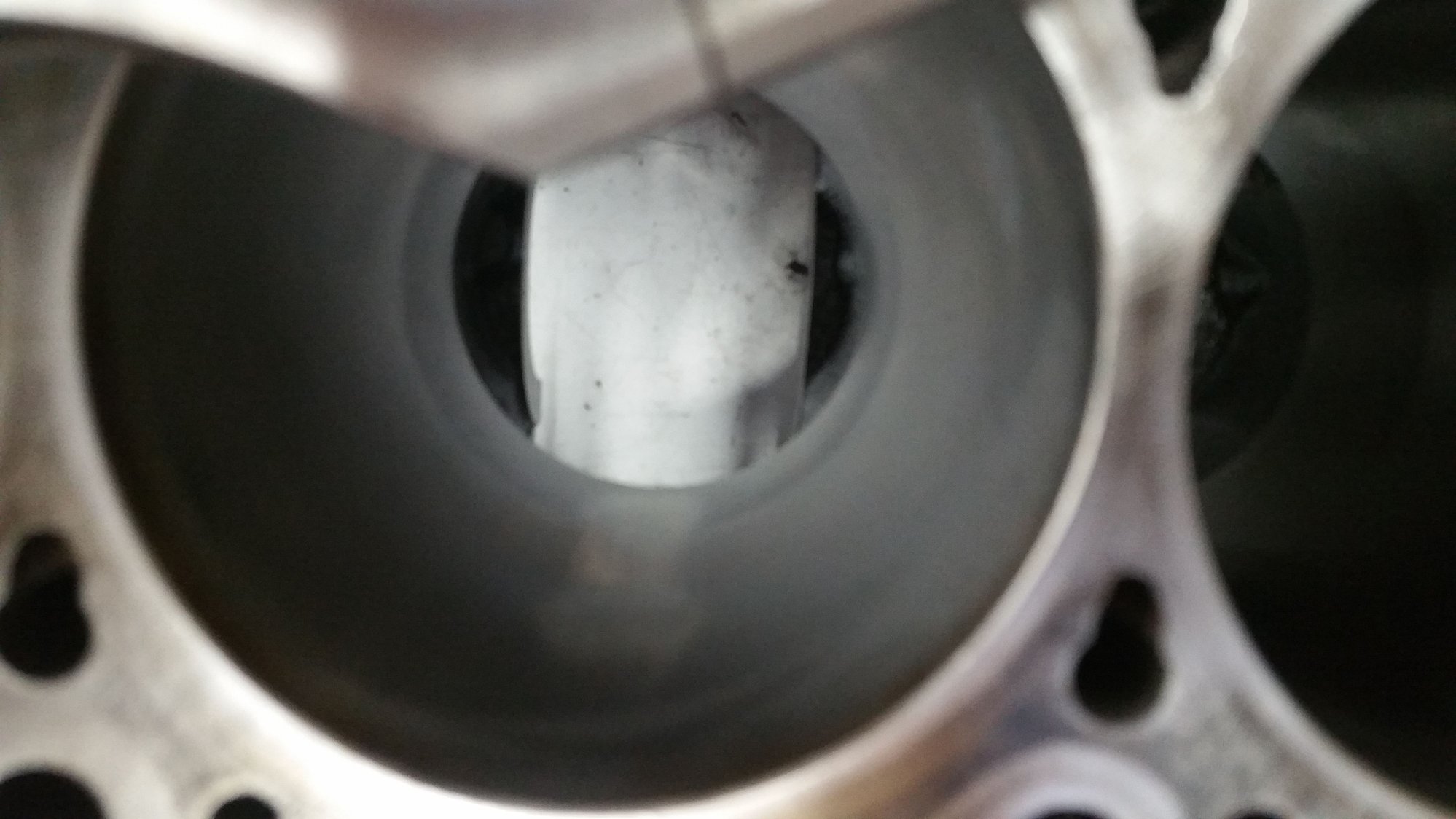

26 m/s is the same as 5,118 fpm. I read somewhere that 26 m/s is target to allow oil to work properly on pistons.

I'm sure it won't fail if you push it higher. The risk is you wear out cross hatch faster. If you have $5k on that race, risk it.

I'm sure it won't fail if you push it higher. The risk is you wear out cross hatch faster. If you have $5k on that race, risk it.

#30

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

Calculating the limit really surprised me how little advantage 3mm or 6mm long rods really provides. We're better off spending that extra $500 on better designed pistons to counter the wear on walls.