Crankshaft Stresses 101

#46

I've never seen an engine come apart without some cylinder wall wear similar to your photos. It's something that simply happens.

I think you're putting too much emphasis on a small, and mostly irrelevant thing. Your cylinder walls actually look great. The scuff is very small. And, when one of these engines is pushing 550-600whp+, it's probably not going to go 100k miles if driven accordingly anyways. Something else is going to wear out, or break, first. It's the nature of a racing engine. At that level, it's likely going to need refreshed (hone and new rings at minimum) well before some mid-cylinder wall scuffing is going to effect it.

You also need to remember that factory PTW is tight, and spec'd for much less power and RPM than you were making. The extra heat make the piston run hotter, further tightening the already tight PTW, leading to some scuffing.

When you see the scuffing, it's more important to look at the condition of the pistons. Do they show signs of Black Death (transferring/embedding iron into the piston), or are they only

Lightly worn with machining lines/grooves smoothed down?

That scuffing can also be caused by too much timing (trying to get every last degree for that last 4whp isn't exactly recommended), and/or knock.

I think you're putting too much emphasis on a small, and mostly irrelevant thing. Your cylinder walls actually look great. The scuff is very small. And, when one of these engines is pushing 550-600whp+, it's probably not going to go 100k miles if driven accordingly anyways. Something else is going to wear out, or break, first. It's the nature of a racing engine. At that level, it's likely going to need refreshed (hone and new rings at minimum) well before some mid-cylinder wall scuffing is going to effect it.

You also need to remember that factory PTW is tight, and spec'd for much less power and RPM than you were making. The extra heat make the piston run hotter, further tightening the already tight PTW, leading to some scuffing.

When you see the scuffing, it's more important to look at the condition of the pistons. Do they show signs of Black Death (transferring/embedding iron into the piston), or are they only

Lightly worn with machining lines/grooves smoothed down?

That scuffing can also be caused by too much timing (trying to get every last degree for that last 4whp isn't exactly recommended), and/or knock.

The following users liked this post:

2006EvoIXer (Jun 2, 2018)

#47

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

You see accelerated wear like that from having too loose PWC. Also, the majority of your wear will come from when the engine is cold or if you're fluttering the rings.

You can do all the math you want, you still won't get real world results on paper. There's so many variables that people don't even think about, like cross hatch angle on the cylinder wall, piston design (offset gudgeon pins, ringland thickness, gas porting, skirt width), ring material and how thick they are, was the cylinder plateau honed or not, was the bore machined with a taper to even out with future wear?, are the pistons being cooled by squirters or splashed oil, what about piston material (4032 or 2618, or something exotic like DW-215).

And they all play a part in how things wear as well as influence power output. Point is, there are so many variables, some of them that you can't control either, that the only good you can get from math is a very, very, very rough ballpark estimate, which sometimes still isn't even right.

You can do all the math you want, you still won't get real world results on paper. There's so many variables that people don't even think about, like cross hatch angle on the cylinder wall, piston design (offset gudgeon pins, ringland thickness, gas porting, skirt width), ring material and how thick they are, was the cylinder plateau honed or not, was the bore machined with a taper to even out with future wear?, are the pistons being cooled by squirters or splashed oil, what about piston material (4032 or 2618, or something exotic like DW-215).

And they all play a part in how things wear as well as influence power output. Point is, there are so many variables, some of them that you can't control either, that the only good you can get from math is a very, very, very rough ballpark estimate, which sometimes still isn't even right.

I've never seen an engine come apart without some cylinder wall wear similar to your photos. It's something that simply happens.

I think you're putting too much emphasis on a small, and mostly irrelevant thing. Your cylinder walls actually look great. The scuff is very small. And, when one of these engines is pushing 550-600whp+, it's probably not going to go 100k miles if driven accordingly anyways. Something else is going to wear out, or break, first. It's the nature of a racing engine. At that level, it's likely going to need refreshed (hone and new rings at minimum) well before some mid-cylinder wall scuffing is going to effect it.

You also need to remember that factory PTW is tight, and spec'd for much less power and RPM than you were making. The extra heat make the piston run hotter, further tightening the already tight PTW, leading to some scuffing.

When you see the scuffing, it's more important to look at the condition of the pistons. Do they show signs of Black Death (transferring/embedding iron into the piston), or are they only

Lightly worn with machining lines/grooves smoothed down?

That scuffing can also be caused by too much timing (trying to get every last degree for that last 4whp isn't exactly recommended), and/or knock.

I think you're putting too much emphasis on a small, and mostly irrelevant thing. Your cylinder walls actually look great. The scuff is very small. And, when one of these engines is pushing 550-600whp+, it's probably not going to go 100k miles if driven accordingly anyways. Something else is going to wear out, or break, first. It's the nature of a racing engine. At that level, it's likely going to need refreshed (hone and new rings at minimum) well before some mid-cylinder wall scuffing is going to effect it.

You also need to remember that factory PTW is tight, and spec'd for much less power and RPM than you were making. The extra heat make the piston run hotter, further tightening the already tight PTW, leading to some scuffing.

When you see the scuffing, it's more important to look at the condition of the pistons. Do they show signs of Black Death (transferring/embedding iron into the piston), or are they only

Lightly worn with machining lines/grooves smoothed down?

That scuffing can also be caused by too much timing (trying to get every last degree for that last 4whp isn't exactly recommended), and/or knock.

Last edited by 2006EvoIXer; Jun 2, 2018 at 01:29 PM.

#49

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

So, for what I purchased. Manley pistons weight 329 grams each (+125 grams for wrist pin + 1.6 grams for wrist pin locks + rings, which is unknown but I'll use 5 grams) and Carrillo rods weight 567 grams each for a total of 1,027.6 grams (or 1.03 kg rounded off).

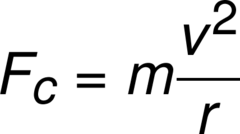

Velocity is PI × diameter (94mm is 0.094m for 94mm cranks) × RPM (let's use 9,500) × min/60 sec =

3.141592 × 0.094m × 158.333 rev/s = 46.76m/s

So Centripetal Force = 1.03 kg × (46.76m/s)^2 ÷ 0.047m = 47,805 Kg-m/s^2 or 47,805 N = 10,747 pounds! (1 N = 0.22481 pounds) Each rod bolt has to hold 5,374 pounds!

3/8" Diameter bolt has cross sectional area of 0.11 square inch. ARP 625 has tensile strength of 260,000 psi. So each bolt can hold 28,600 pounds. So revving to 9,500 rpm gives me a factor of safety of 5.32.

Checking to side loads at 9500 rpms when big end of rods swing one side to other horizontally, mass is 0.396kg × (46.76m/s)^2 ÷ 0.047m. I get 4,142 pounds the big ends need to hold. Unfortunately, I don't know the strength of rod alloy.

However, the cross sectional area is more than the 0.11 square inch of the bolts.

How about the forces at wrist pins? If it spins in a circle, we an calculate it the same way, but it flips back and forth. The mass at pin side of rod is 0.171 kg and I get 1,788 pounds. So if we assume changing direction to equal and opposite, this doubles the force seen by pin right? So can we assume it's 3,577 pounds the pistons skirts (both sides) need to withstand at 58% down from TDC?

Last edited by 2006EvoIXer; Sep 11, 2018 at 01:33 AM.

#50

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

Sorry, I've gotten off point. The forces on the crank journals should be the same as the big end portion of rods. I won't get further off point and go into skirt loading here. Lol

Forces on crank should be 10,667 pounds up at TDC (0°) and down at BDC (180°) at start of suction/compression stroke; and 4,142 pounds at 90° and 270° outward direction for both. At start of power stroke, it's anyone's guess since power can be anything.

Forces on crank should be 10,667 pounds up at TDC (0°) and down at BDC (180°) at start of suction/compression stroke; and 4,142 pounds at 90° and 270° outward direction for both. At start of power stroke, it's anyone's guess since power can be anything.

Last edited by 2006EvoIXer; Jun 26, 2018 at 09:53 AM.

#51

Thread Starter

Evolved Member

iTrader: (1)

Joined: Jul 2012

Posts: 3,294

Likes: 195

From: California

Let me know if you guys want to attempt to calculate power (1 horsepower = 550 foot-pounds/sec). Lol

I'll need help since it's been too long and I'll be making my best guess. Actually, all of this is my best guess and needs to be checked. If you find mistakes, let me know where and I'll correct it.

I'll need help since it's been too long and I'll be making my best guess. Actually, all of this is my best guess and needs to be checked. If you find mistakes, let me know where and I'll correct it.

Thread

Thread Starter

Forum

Replies

Last Post

CeliOnce

For Sale/WTB - Engine / Drivetrain / Power

19

Jun 25, 2015 07:48 AM

project_lancer

Lancer Tires, Wheels, Brakes & Suspension - Sponsored by The Tire Rack

47

May 19, 2013 03:18 AM

LGshow19

For Sale - Wanting To Buy (WTB) Or Trade (WTT)

1

Jun 9, 2012 11:19 PM