500 whp on stock engine on pump gas and Alcohol Injection

#16

Thread Starter

Account Disabled

iTrader: (91)

Joined: Sep 2003

Posts: 16,850

Likes: 0

From: 2003 Evo VIII - Silver

Originally Posted by Smogrunner

I agree with Al. He said stock motor with big turbo in the first thread. Lets talk about the alcohol injection.

Al, you said it improves spool? Could you explain that?

Al, you said it improves spool? Could you explain that?

Here is my theory

The alcohol kit we use uses a standard fuel pump at about 90 - 95 psi with a 15 gallon per hour capacity spray jet (at 90 - 95 psi )

This equates with Methanol (we were using denatured alcohol in the above test) to a specifc gravity of approx .928

At 95 psi this equals about 93 POUNDS of fuel per hour at peak pump pressure

Or as much fuel as one 1000 injector can flow at 45 psi line -pressure. This will support about 125 additional whp give or take on Alcohol.

When the car is spooling up - the alcohol is injected into the cylinder at a time when my ignition timing settings are fairly retarded. The net result, along with alcohol's high oxygen content and cooling effect, is to slow the burning rate of the explosion. Put simply, alcohol explodes in long, slow, steadier explosions than gasoline, which goes off almost all at once in a pop. Given this property, ignition timing can be advanced quite a bit in an alcohol-fueled car. Advanced timing allows fuel ignition to begin earlier and spreads the ignition over a longer period. Since alcohol's self-carried oxygen helps the burn continue longer (as long as there is unburned fuel), when I RETARD the timing slightly at spool up the alcohol being injected at full pressure into the intake tract is still beng burned as the exhuast valve opens. This helps spool the turbo more raplidly.

Further, alcohol's high latent heat of vaporization cools a car's cylinders upon its induction stroke, this greatly cools the intake charge and makes the air going into the cylinder much more dense and supplies more o2 to burn. This also helps spool the turbo.

Alcohol is referred to as an oxygenated hydrocarbon. Alcohol's extra oxygen along with its longer burning time contribute to the spooling of the turbo.

When I have driven my car with the alcohol turned on - I can feel the low end trq and impact of the turbo hitting harder down low.

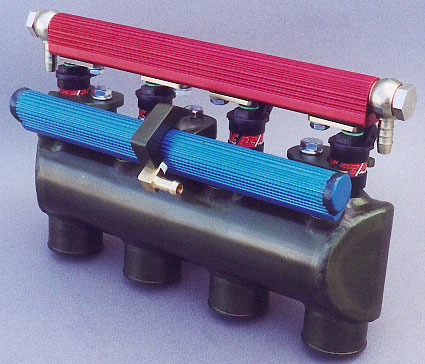

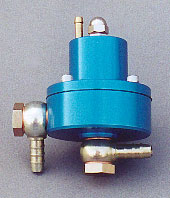

As the boost rises the manifold preessure is increased which partially reduces the flow from the now fully pumped up alcohol fuel pump. This reduces the effective alcohol injection preessure to about 70 psi at 25 psi of boost. This is a near 25% reduction. (PS - very few of us could afford the extra cost or expense of a rising rate regulated alcohol fuel system - but they are available - look

These complex syetems sure are fascinating and wonderful to look at but not very practical on a street car.

The greatest thing about my kit is its low cost, simple instalation and ease of use. It also really works well given its very simple principles of operation.

In any event - as the boost level rises the power is picking up - the turbo is fully spooled and I ramp up the ignition timing to take full advatage of the high octane and stable burning gas/alcohol mix.

At this point the proportion of alcohol to gas is more gas laden - however there is still enough alcohol to raise the effective octane enough to make 500 whp and enough to cool the charg temps dramatically.

I hope this helps explain some of my reasoning on why the alcohol injection helps spool a turbo faster - (with proper tuning).

Last edited by DynoFlash; Feb 20, 2005 at 11:43 AM.

#18

Originally Posted by DynoFlash

Pruven has done it dozens and dozens of times and I have never heard of any problems. However - changing the studs with the head on is clearly not the "ideal" manner in which to change the studs. The prefered manner is to remove the head - change the head gasket and install the studs after tapping the block to assure clean threads.

This said, I have never heard of anyone doing the job with the head on the car and changing the studs one at a time.

This said, I have never heard of anyone doing the job with the head on the car and changing the studs one at a time.

-Paul

#19

Originally Posted by DynoFlash

Its very interesting the way this thing works on the tq and spool up

Here is my theory

The alcohol kit we use uses a standard fuel pump at about 90 - 95 psi with a 15 gallon per hour capacity spray jet

This equates with Methanol (we were using denatured alcohol in the above test) to a specifc gravity of approx .928

At 95 psi this equals about 93 gallons of fuel per hour at peak pump pressure

When the car is spooling up - the alcohol is injected into the cylinder at a time when my ignition timing settings are fairly retarded. The net result, along with alcohol's high oxygen content and cooling effect, is to slow the burning rate of the explosion. Put simply, alcohol explodes in long, slow, steadier explosions than gasoline, which goes off almost all at once in a pop. Given this property, ignition timing can be advanced quite a bit in an alcohol-fueled car. Advanced timing allows fuel ignition to begin earlier and spreads the ignition over a longer period. Since alcohol's self-carried oxygen helps the burn continue longer (as long as there is unburned fuel), when I RETARD the timing slightly at spool up the alcohol being injected at full pressure into the intake tract is still beng burned as the exhuast valve opens. This helps spool the turbo more raplidly.

Further, alcohol's high latent heat of vaporization cools a car's cylinders upon its induction stroke, this greatly cools the intake charge and makes the air going into the cylinder much more dense and supplies more o2 to burn. This also helps spool the turbo.

Alcohol is referred to as an oxygenated hydrocarbon. Alcohol's extra oxygen along with its longer burning time contribute to the spooling of the turbo.

When I have driven my car with the alcohol turned on - I can feel the low end trq and impact of the turbo hitting harder down low.

As the boost rises the manifold preessure is increased which partially reduces the flow from the now fully pumped up alcohol fuel pump. This reduces the effective alcohol injection preessure to about 70 psi at 25 psi of boost. This is a near 25% reduction. (PS - very few of us could afford the extra cost or expense of a rising rate regulated alcohol fuel system - but they are available - look

These complex syetems sure are fascinating and wonderful to look at but not very practical on a street car.

The greatest thing about my kit is its low cost, simple instalation and ease of use. It also really works well given its very simple principles of operation.

In any event - as the boost level rises the power is picking up - the turbo is fully spooled and I ramp up the ignition timing to take full advatage of the high octane and stable burning gas/alcohol mix.

At this point the proportion of alcohol to gas is more gas laden - however there is still enough alcohol to raise the effective octane enough to make 500 whp and enough to cool the charg temps dramatically.

I hope this helps explain some of my reasoning on why the alcohol injection helps spool a turbo faster - (with proper tuning).

Here is my theory

The alcohol kit we use uses a standard fuel pump at about 90 - 95 psi with a 15 gallon per hour capacity spray jet

This equates with Methanol (we were using denatured alcohol in the above test) to a specifc gravity of approx .928

At 95 psi this equals about 93 gallons of fuel per hour at peak pump pressure

When the car is spooling up - the alcohol is injected into the cylinder at a time when my ignition timing settings are fairly retarded. The net result, along with alcohol's high oxygen content and cooling effect, is to slow the burning rate of the explosion. Put simply, alcohol explodes in long, slow, steadier explosions than gasoline, which goes off almost all at once in a pop. Given this property, ignition timing can be advanced quite a bit in an alcohol-fueled car. Advanced timing allows fuel ignition to begin earlier and spreads the ignition over a longer period. Since alcohol's self-carried oxygen helps the burn continue longer (as long as there is unburned fuel), when I RETARD the timing slightly at spool up the alcohol being injected at full pressure into the intake tract is still beng burned as the exhuast valve opens. This helps spool the turbo more raplidly.

Further, alcohol's high latent heat of vaporization cools a car's cylinders upon its induction stroke, this greatly cools the intake charge and makes the air going into the cylinder much more dense and supplies more o2 to burn. This also helps spool the turbo.

Alcohol is referred to as an oxygenated hydrocarbon. Alcohol's extra oxygen along with its longer burning time contribute to the spooling of the turbo.

When I have driven my car with the alcohol turned on - I can feel the low end trq and impact of the turbo hitting harder down low.

As the boost rises the manifold preessure is increased which partially reduces the flow from the now fully pumped up alcohol fuel pump. This reduces the effective alcohol injection preessure to about 70 psi at 25 psi of boost. This is a near 25% reduction. (PS - very few of us could afford the extra cost or expense of a rising rate regulated alcohol fuel system - but they are available - look

These complex syetems sure are fascinating and wonderful to look at but not very practical on a street car.

The greatest thing about my kit is its low cost, simple instalation and ease of use. It also really works well given its very simple principles of operation.

In any event - as the boost level rises the power is picking up - the turbo is fully spooled and I ramp up the ignition timing to take full advatage of the high octane and stable burning gas/alcohol mix.

At this point the proportion of alcohol to gas is more gas laden - however there is still enough alcohol to raise the effective octane enough to make 500 whp and enough to cool the charg temps dramatically.

I hope this helps explain some of my reasoning on why the alcohol injection helps spool a turbo faster - (with proper tuning).

#20

Thread Starter

Account Disabled

iTrader: (91)

Joined: Sep 2003

Posts: 16,850

Likes: 0

From: 2003 Evo VIII - Silver

Originally Posted by PVD04

Did you mean to say that you have never heard of anyone having problems with changing the head studs one at a time? Just want to clarify.

-Paul

-Paul

However - I have seen quite a few head gaskets go with the stock head studs

On the other hand - incidentally - I have not seen any rod bolt failures on the stock rod bolts and I am not sure if I would still recomend rod bolts on stock bottom ends

#22

Thread Starter

Account Disabled

iTrader: (91)

Joined: Sep 2003

Posts: 16,850

Likes: 0

From: 2003 Evo VIII - Silver

Originally Posted by HiHeatEVO

you hit the track with the whine-O kit installed yet??

I was thinking to make a post on the forums about my project - somthing like race car prep or somthing and post up details and pics of the project as I go

Its a lot of fun getting ready to race

#23

Originally Posted by DynoFlash

Its very interesting the way this thing works on the tq and spool up

Here is my theory

The alcohol kit we use uses a standard fuel pump at about 90 - 95 psi with a 15 gallon per hour capacity spray jet

This equates with Methanol (we were using denatured alcohol in the above test) to a specifc gravity of approx .928

At 95 psi this equals about 93 gallons of fuel per hour at peak pump pressure

Here is my theory

The alcohol kit we use uses a standard fuel pump at about 90 - 95 psi with a 15 gallon per hour capacity spray jet

This equates with Methanol (we were using denatured alcohol in the above test) to a specifc gravity of approx .928

At 95 psi this equals about 93 gallons of fuel per hour at peak pump pressure

why don't you leave the engineering up to real engineers

specific gravity is a measurement of density where water has a SG of 1.0 that means of you have one gallon of denatured alcohol at .928 SG, it weights approximately .928 of that of water using the same volume (one gallon). if your alcohol injector has a capacity of 15 gallons per hour, your only going to pump 15 gallons, not 93. i think what you meant to say was that if a gallon of water weights 8.34lb, then at 15 gallons per hour your pumping 125.1 lb/hr of water. now using your denatured alcohol at a specific gravity at .928 will be about 116.09 lb/hr.

but of course i am not totally right because you left out a key peice of information. that would be what pressure the injector flow rate was calculated at. for instance, if your injector was calculated at 15 gallons/hr at 95psi then my calculations will be right. but if it were calculated at, for say, about 15 psi then your would be correct at saying the injector pushes 93 gal/hr at 95psi. however sense you listed specific gravity (which has nothing to do with volume flow rates, just mass flow rates), i'm lead to believe your wrong. additionally i'm betting this injector is rated at 15gal/hr at a much higher pressure then 15psi, because a super soaker puts out more then 15 psi of pressure.

#24

additionally, using your windshield washer pump for water injection would work as good as pissing in your intake. the pressure is not nearly high enough to allow the water/alcohol to atomize when it is injected. atomization is the reason it works so well. the injection makes it a fine mist due to the high pressures when it is injected, and it travels with the air, causing greatly reduced air temps. additionally the atomized water has much higher surface area then water injected that is not atomized as well. the surface area/volume of water injected is the other aspect that is key. if you just injected water at low pressures it would just hydrolock your engine. it wouldn't travel very quickly downthe intake track if at all, it wouldn't cool the air, and it would pool in the cylinder. high pressure is key.

the only usable part of the windshield washer system is the tank itself. the pump isn't high enough pressure, and the nossles certainly are not shaped correctly (with a very tight stream... water injection will use a large cone shaped spray relative to the washer nozzles)

the only usable part of the windshield washer system is the tank itself. the pump isn't high enough pressure, and the nossles certainly are not shaped correctly (with a very tight stream... water injection will use a large cone shaped spray relative to the washer nozzles)

#25

oh one last thing of interest: if your injector truely is rated at 15gal/hr at 15psi, then at 95 psi (or rather 93 gallons/hr as you claimed) you would drain a 1 gallon resevior in .64 seconds this injector size would put it up in the 5000 hp top fuel dragster injector sizes...

#28

Thread Starter

Account Disabled

iTrader: (91)

Joined: Sep 2003

Posts: 16,850

Likes: 0

From: 2003 Evo VIII - Silver

Originally Posted by KevinD

sorry al, your math is not even close.

why don't you leave the engineering up to real engineers

specific gravity is a measurement of density where water has a SG of 1.0 that means of you have one gallon of denatured alcohol at .928 SG, it weights approximately .928 of that of water using the same volume (one gallon). if your alcohol injector has a capacity of 15 gallons per hour, your only going to pump 15 gallons, not 93. i think what you meant to say was that if a gallon of water weights 8.34lb, then at 15 gallons per hour your pumping 125.1 lb/hr of water. now using your denatured alcohol at a specific gravity at .928 will be about 116.09 lb/hr.

but of course i am not totally right because you left out a key peice of information. that would be what pressure the injector flow rate was calculated at. for instance, if your injector was calculated at 15 gallons/hr at 95psi then my calculations will be right. but if it were calculated at, for say, about 15 psi then your would be correct at saying the injector pushes 93 gal/hr at 95psi. however sense you listed specific gravity (which has nothing to do with volume flow rates, just mass flow rates), i'm lead to believe your wrong. additionally i'm betting this injector is rated at 15gal/hr at a much higher pressure then 15psi, because a super soaker puts out more then 15 psi of pressure.

why don't you leave the engineering up to real engineers

specific gravity is a measurement of density where water has a SG of 1.0 that means of you have one gallon of denatured alcohol at .928 SG, it weights approximately .928 of that of water using the same volume (one gallon). if your alcohol injector has a capacity of 15 gallons per hour, your only going to pump 15 gallons, not 93. i think what you meant to say was that if a gallon of water weights 8.34lb, then at 15 gallons per hour your pumping 125.1 lb/hr of water. now using your denatured alcohol at a specific gravity at .928 will be about 116.09 lb/hr.

but of course i am not totally right because you left out a key peice of information. that would be what pressure the injector flow rate was calculated at. for instance, if your injector was calculated at 15 gallons/hr at 95psi then my calculations will be right. but if it were calculated at, for say, about 15 psi then your would be correct at saying the injector pushes 93 gal/hr at 95psi. however sense you listed specific gravity (which has nothing to do with volume flow rates, just mass flow rates), i'm lead to believe your wrong. additionally i'm betting this injector is rated at 15gal/hr at a much higher pressure then 15psi, because a super soaker puts out more then 15 psi of pressure.

Actually - what happend here is that it was late at night after a long day of dynoing when i posted this and I meant to say pounds per hour for the rate of injection which is at 90 - 95 psi pump presssure. I have edited the gallons tgo pounds above. My point was that as the car builds boost this figure effective rate drops 20 - 25% due to boost levels in the manifold.

I did not leave out the flow pressure rating above as the psi level is clearly listed at 90 - 95 psi and that is the pressure upon which the nozzel sprays 15 gals per hour.

Hope this clears it up for you

Thanks for your cooperative guidance

Last edited by DynoFlash; Feb 20, 2005 at 11:34 AM.

#29

Thread Starter

Account Disabled

iTrader: (91)

Joined: Sep 2003

Posts: 16,850

Likes: 0

From: 2003 Evo VIII - Silver

Originally Posted by KevinD

additionally, using your windshield washer pump for water injection would work as good as pissing in your intake. the pressure is not nearly high enough to allow the water/alcohol to atomize when it is injected. atomization is the reason it works so well. the injection makes it a fine mist due to the high pressures when it is injected, and it travels with the air, causing greatly reduced air temps. additionally the atomized water has much higher surface area then water injected that is not atomized as well. the surface area/volume of water injected is the other aspect that is key. if you just injected water at low pressures it would just hydrolock your engine. it wouldn't travel very quickly downthe intake track if at all, it wouldn't cool the air, and it would pool in the cylinder. high pressure is key.

the only usable part of the windshield washer system is the tank itself. the pump isn't high enough pressure, and the nossles certainly are not shaped correctly (with a very tight stream... water injection will use a large cone shaped spray relative to the washer nozzles)

the only usable part of the windshield washer system is the tank itself. the pump isn't high enough pressure, and the nossles certainly are not shaped correctly (with a very tight stream... water injection will use a large cone shaped spray relative to the washer nozzles)

Our new system which can spray either alcohol of windsheild washer fluid or water actually operates at over 100 psi. It utilizes a very high cost and effectoive pump which draws less amps and delivers more pressure. It also is very corrosion resisitant.

Thanks again for your observations

#30

Thread Starter

Account Disabled

iTrader: (91)

Joined: Sep 2003

Posts: 16,850

Likes: 0

From: 2003 Evo VIII - Silver

Originally Posted by KevinD

oh one last thing of interest: if your injector truely is rated at 15gal/hr at 15psi, then at 95 psi (or rather 93 gallons/hr as you claimed) you would drain a 1 gallon resevior in .64 seconds this injector size would put it up in the 5000 hp top fuel dragster injector sizes...

If you ran your car wide open at full boost non stop it would prob spray about 11 gallons per hour whixch would mean that the 1 gal sprayer tank would last for about 5 - 6 minutes under full boost continuos operation

In practice we see that the tank usually needs to be filled after every two tanks of fuel on street driving