How To: Boost leak tester for $5.02

#16

ok so i did a pressure test on my car. i can get it up to 28 psi then it slowly starts to lose pressure. it takes a good 2-3 minutes before it is back at 0psi. i dont hear any leaks including tb gasket and injector area. is the system supposed to be able to be pressurized and hold a certain psi until you vent off the pressure? also i blocked off the mbc line and the tube coming from the valve cover

#19

Thread Starter

Evolved Member

iTrader: (7)

Joined: Oct 2006

Posts: 1,439

Likes: 1

From: Flyover country.

ok so i did a pressure test on my car. i can get it up to 28 psi then it slowly starts to lose pressure. it takes a good 2-3 minutes before it is back at 0psi. i dont hear any leaks including tb gasket and injector area. is the system supposed to be able to be pressurized and hold a certain psi until you vent off the pressure? also i blocked off the mbc line and the tube coming from the valve cover

What happens is the air escapes through your exhaust because of valve overlap (especially on big cams), you can actually hear it if you put your ear to the exhaust pipe or even feel it by the tailpipe.

It'll also escape through the piston rings and into the crankcase and from there usually out of the valve cover gasket. If you'd open the oil cap or unplugged the valve cover vent you'd hear it escaping from there.

If you have a bad turbo the air would escape through the seals and into the crankcase, to check that, you'd have to exclude your intake mani/engine from the pressurized system by plugging it off at the UICP like so (we used an oil filter):

When you pressurize it like that and hear the air escaping through your crank case (open valve cover vent and oil cap), you know it's the turbo oil seals.

Happy testing, guys!

#22

Thread Starter

Evolved Member

iTrader: (7)

Joined: Oct 2006

Posts: 1,439

Likes: 1

From: Flyover country.

And i feel like 2'' to 1.5'' has a neckdown which helps keep the cap inside of it under pressure, that's why i used that one.

But like i said this is just a base write-up, feel free to improve on it and add modifications and use different parts!!! Post them up too!

#23

Did something similar not to long ago:

1. Depending on what the size of your compressor inlet on your turbo is, you will need to get about a 2-3 inch section of silicon or rubber coupler hose. I was able to source a 3 inch diameter coupler at AutoZone picutred below. Notice that there is a black reducer ring in there so that one is enabled to connect to a 2.5 inch pipe as well. It comes with worm clamps as well.

$4.00

Next, I went to Home Depot and souced a 3 inch knock-out cap from the plumbing/PVC section.

30 Cents. Ea.

The next thing to do is to drill a 5/16 inch whole in the 3 inch knock-out cap so that the valve stem below can go thru the whole. A multi-step drill bit is perfect for this, but not that cheap.

$3.00

Since the knock-out cap isn't that thick, you may want to wrap a "few" turns of teflon tape around the base of the valve stem to get a better seal. (I couldn't source a deeper cap that fit)

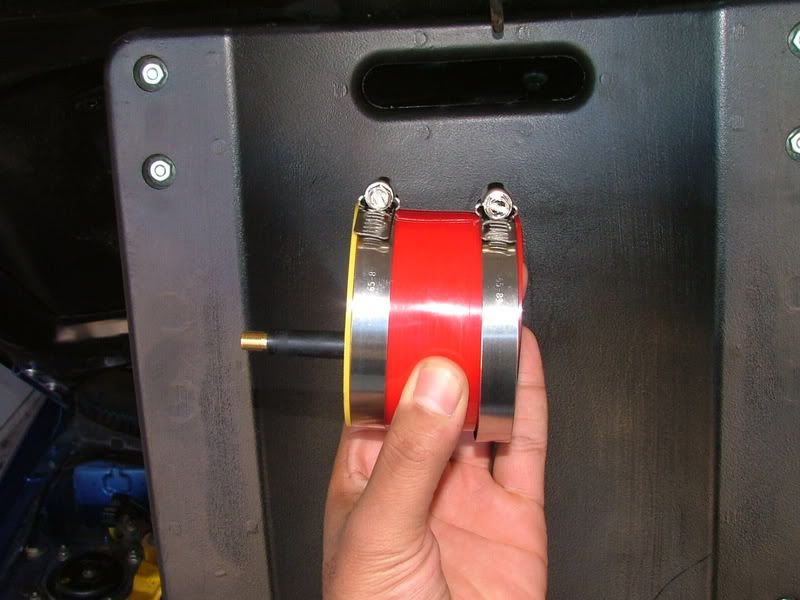

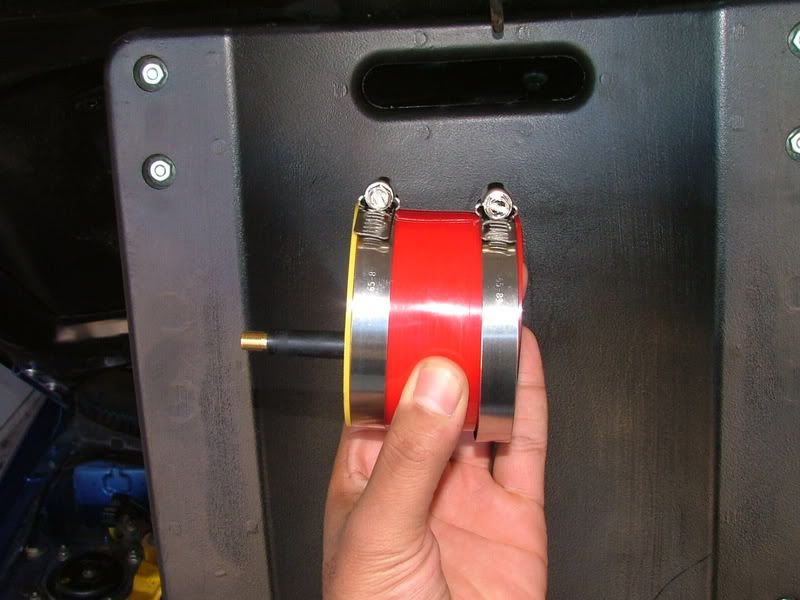

The next thing I did was put the cap with the stem installed on one end of the coupler, and clamp it down tight enough so that it won't pop off:

For ease of use, I decided to install the tester on the 2.5 inch intake pipe, instead of directly on the 3 inch inlet of the GT-28RS. The black reducer ring that came with the coupler was key:

[B][COLOR=Red]BE AWARE THAT IF YOU DO THIS, IT IS AT YOUR OWN RISK!!! I WILL NOT BE HELD LIABLE FOR ANY DAMAGES! DO NOT TURN ON YOUR CAR'S ENGINE WHILE DOING THIS!!!

1. Depending on what the size of your compressor inlet on your turbo is, you will need to get about a 2-3 inch section of silicon or rubber coupler hose. I was able to source a 3 inch diameter coupler at AutoZone picutred below. Notice that there is a black reducer ring in there so that one is enabled to connect to a 2.5 inch pipe as well. It comes with worm clamps as well.

$4.00

Next, I went to Home Depot and souced a 3 inch knock-out cap from the plumbing/PVC section.

30 Cents. Ea.

The next thing to do is to drill a 5/16 inch whole in the 3 inch knock-out cap so that the valve stem below can go thru the whole. A multi-step drill bit is perfect for this, but not that cheap.

$3.00

Since the knock-out cap isn't that thick, you may want to wrap a "few" turns of teflon tape around the base of the valve stem to get a better seal. (I couldn't source a deeper cap that fit)

The next thing I did was put the cap with the stem installed on one end of the coupler, and clamp it down tight enough so that it won't pop off:

For ease of use, I decided to install the tester on the 2.5 inch intake pipe, instead of directly on the 3 inch inlet of the GT-28RS. The black reducer ring that came with the coupler was key:

[B][COLOR=Red]BE AWARE THAT IF YOU DO THIS, IT IS AT YOUR OWN RISK!!! I WILL NOT BE HELD LIABLE FOR ANY DAMAGES! DO NOT TURN ON YOUR CAR'S ENGINE WHILE DOING THIS!!!

#24

Evolved Member

iTrader: (5)

Joined: Sep 2006

Posts: 609

Likes: 1

From: Long Island, NY (Hurry up and wait)

Ok. Very stupid question i have but il ask anyway. Is it possible that a portable cigarette lighter plug in air compressor(one normally found in a trunk emergency kit) is not able to inflate the system with enough air QUICKLY ENOUGH to do the test?? I tried with my tester the the last time but it seemed not to go over 15psi and i only heard a VERY SMALL leak

#25

mplspilot, I do not see where the test is being performed in your example. In other words, is the test being conducted on the compressor/cold side of the turbo?

I ask because I tried testing my "entire" system by pressurising at the cold side of the turbo. However, when I did this air was escaping from the oil cap when I put no more than 21psi into the system as seen in my posts below. Should the oil cap be allowing air to escape?

https://www.evolutionm.net/forums/sh...4&postcount=24

https://www.evolutionm.net/forums/sh...0&postcount=29

I ask because I tried testing my "entire" system by pressurising at the cold side of the turbo. However, when I did this air was escaping from the oil cap when I put no more than 21psi into the system as seen in my posts below. Should the oil cap be allowing air to escape?

https://www.evolutionm.net/forums/sh...4&postcount=24

https://www.evolutionm.net/forums/sh...0&postcount=29

Slowly losing pressure is normal. Depending on how you catch your valves and depending on how big your cams are, it'll decrease slower or faster.

What happens is the air escapes through your exhaust because of valve overlap (especially on big cams), you can actually hear it if you put your ear to the exhaust pipe or even feel it by the tailpipe.

It'll also escape through the piston rings and into the crankcase and from there usually out of the valve cover gasket. If you'd open the oil cap or unplugged the valve cover vent you'd hear it escaping from there.

If you have a bad turbo the air would escape through the seals and into the crankcase, to check that, you'd have to exclude your intake mani/engine from the pressurized system by plugging it off at the UICP like so (we used an oil filter):

When you pressurize it like that and hear the air escaping through your crank case (open valve cover vent and oil cap), you know it's the turbo oil seals.

Happy testing, guys!

What happens is the air escapes through your exhaust because of valve overlap (especially on big cams), you can actually hear it if you put your ear to the exhaust pipe or even feel it by the tailpipe.

It'll also escape through the piston rings and into the crankcase and from there usually out of the valve cover gasket. If you'd open the oil cap or unplugged the valve cover vent you'd hear it escaping from there.

If you have a bad turbo the air would escape through the seals and into the crankcase, to check that, you'd have to exclude your intake mani/engine from the pressurized system by plugging it off at the UICP like so (we used an oil filter):

When you pressurize it like that and hear the air escaping through your crank case (open valve cover vent and oil cap), you know it's the turbo oil seals.

Happy testing, guys!

#27

Ok. Very stupid question i have but il ask anyway. Is it possible that a portable cigarette lighter plug in air compressor(one normally found in a trunk emergency kit) is not able to inflate the system with enough air QUICKLY ENOUGH to do the test?? I tried with my tester the the last time but it seemed not to go over 15psi and i only heard a VERY SMALL leak

I may also suggest a airline fitting for those with compressors. This way you can just plug the hose to the boost checker peice. Frees you up to move around.

#28

Thread Starter

Evolved Member

iTrader: (7)

Joined: Oct 2006

Posts: 1,439

Likes: 1

From: Flyover country.

mplspilot, I do not see where the test is being performed in your example. In other words, is the test being conducted on the compressor/cold side of the turbo?

I ask because I tried testing my "entire" system by pressurising at the cold side of the turbo. However, when I did this air was escaping from the oil cap when I put no more than 21psi into the system as seen in my posts below. Should the oil cap be allowing air to escape?

https://www.evolutionm.net/forums/sh...4&postcount=24

https://www.evolutionm.net/forums/sh...0&postcount=29

I ask because I tried testing my "entire" system by pressurising at the cold side of the turbo. However, when I did this air was escaping from the oil cap when I put no more than 21psi into the system as seen in my posts below. Should the oil cap be allowing air to escape?

https://www.evolutionm.net/forums/sh...4&postcount=24

https://www.evolutionm.net/forums/sh...0&postcount=29

Yep, you'd just put the coupler on the compressor inlet like so:

Air will escape through the oil cap as i mentioned it gets into the crankcase through piston rings. Or through a turbo seal. Or valve guide seals. In some cars it'll escape quicker, in some slower.. If it's not too fast it's not that big of a deal..

Focus your attention on listening in other areas.