Adjustable height ball joint replacement in the works . . .

#1

Adjustable height ball joint replacement in the works . . .

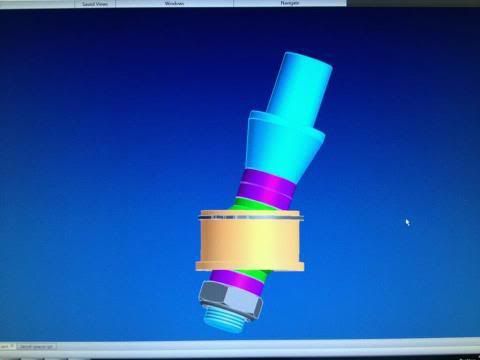

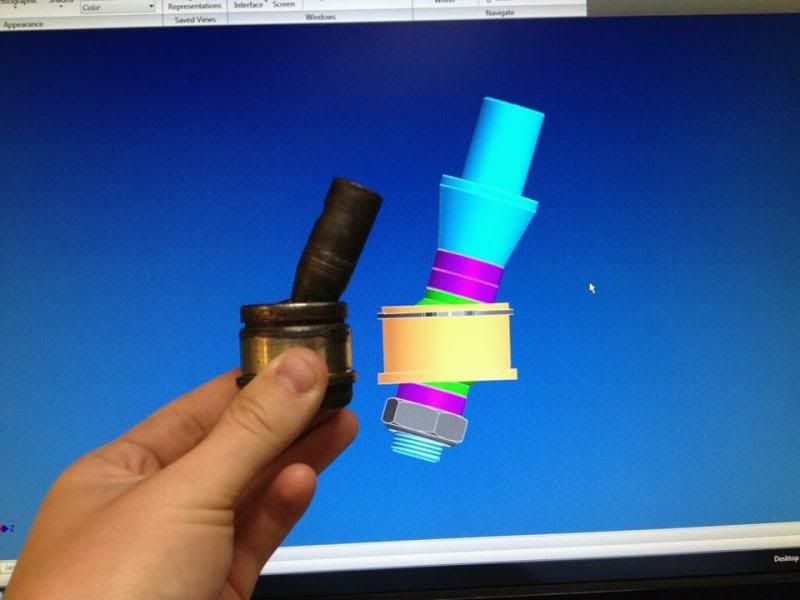

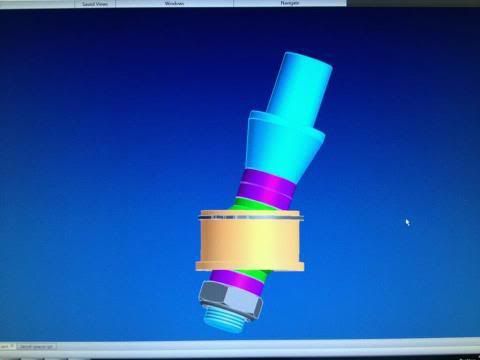

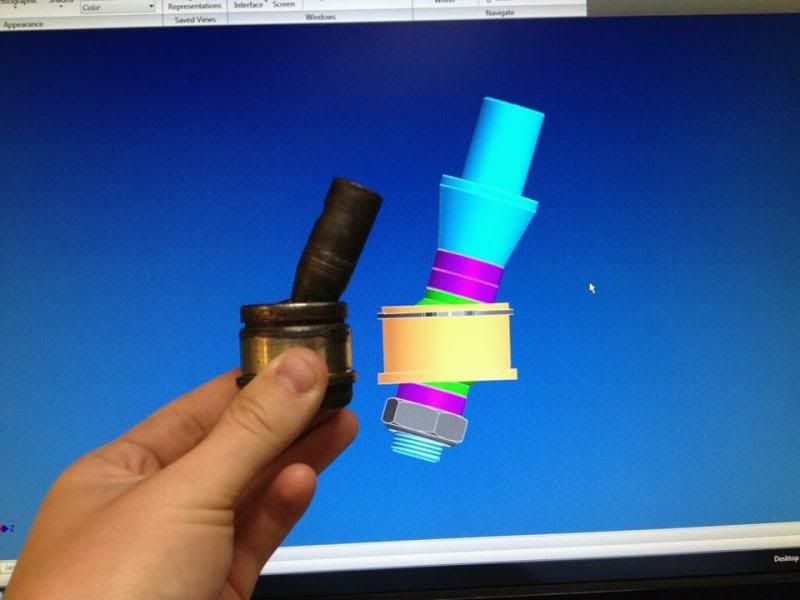

Here are a couple screen shots of something a buddy and I are working on. It is an adjustable height ball joint setup for the EVO to allow cars at different ride heights to always have the proper suspension geometry. Along the lines of what the Whiteline Roll Center Kit acheives, except this one is adjustable.

Still in the early planning stages - but thought I would share this with you all. Any feedback is welcome. . .

Comparison of misalignment angle vs. Whiteline RCK ball joint:

Here is a video:

http://www.facebook.com/photo.php?v=3827071107964

Still in the early planning stages - but thought I would share this with you all. Any feedback is welcome. . .

Comparison of misalignment angle vs. Whiteline RCK ball joint:

Here is a video:

http://www.facebook.com/photo.php?v=3827071107964

#2

Evolved Member

iTrader: (8)

Love the idea, but proper execution is critical on this part.

It needs two flat areas you can get a wrench on to properly torque the bottom nut before mounting it in the hub carrier.

Making it adjustable might not be doing anything but increasing the part count and creating areas for possible corrosion issues. A fixed height that is worth while (say 1.5" vs. the 5/16" of the white lines) would probably work for all interested in such a part. Adjustable tie-rod though to correct bumpsteer would be awesome.

It needs two flat areas you can get a wrench on to properly torque the bottom nut before mounting it in the hub carrier.

Making it adjustable might not be doing anything but increasing the part count and creating areas for possible corrosion issues. A fixed height that is worth while (say 1.5" vs. the 5/16" of the white lines) would probably work for all interested in such a part. Adjustable tie-rod though to correct bumpsteer would be awesome.

#3

EvoM Guru

iTrader: (4)

Love the idea, but proper execution is critical on this part.

It needs two flat areas you can get a wrench on to properly torque the bottom nut before mounting it in the hub carrier.

Making it adjustable might not be doing anything but increasing the part count and creating areas for possible corrosion issues. A fixed height that is worth while (say 1.5" vs. the 5/16" of the white lines) would probably work for all interested in such a part. Adjustable tie-rod though to correct bumpsteer would be awesome.

It needs two flat areas you can get a wrench on to properly torque the bottom nut before mounting it in the hub carrier.

Making it adjustable might not be doing anything but increasing the part count and creating areas for possible corrosion issues. A fixed height that is worth while (say 1.5" vs. the 5/16" of the white lines) would probably work for all interested in such a part. Adjustable tie-rod though to correct bumpsteer would be awesome.

#4

Love the idea, but proper execution is critical on this part.

It needs two flat areas you can get a wrench on to properly torque the bottom nut before mounting it in the hub carrier.

Making it adjustable might not be doing anything but increasing the part count and creating areas for possible corrosion issues. A fixed height that is worth while (say 1.5" vs. the 5/16" of the white lines) would probably work for all interested in such a part. Adjustable tie-rod though to correct bumpsteer would be awesome.

It needs two flat areas you can get a wrench on to properly torque the bottom nut before mounting it in the hub carrier.

Making it adjustable might not be doing anything but increasing the part count and creating areas for possible corrosion issues. A fixed height that is worth while (say 1.5" vs. the 5/16" of the white lines) would probably work for all interested in such a part. Adjustable tie-rod though to correct bumpsteer would be awesome.

Thanks for the info.

BTW - adjustable tie rods ends are currently available. I have been running them on my car for several years . . .

http://www.green.dti.ne.jp/unlimitedworks/ (under "original parts")

#7

If you look at the pics of the Nagisa and Cyber EVO control arms - you can see that they use the exact same spherical bearing setup we are working on. Only difference is - we want to make a setup that mounts into the stock control arm rather than a bearing cup welded on the end of the aftermarket arms.

Trending Topics

#9

Evolved Member

iTrader: (8)

Yeah, the stock arms are pretty awesome for stiffness and weight and beating them in that regard would be tough to do. The only reason I'd look at an arm replacement is if it was adjustable for track width and caster. Even then though, with the X arms and the PSRS you can accomplish the same thing.

Adding a large diameter washer to the bottom might be a good idea. It's pretty common for that to be a requirement on suspension components in a lot of racing organizations so that should the plain bearing ever fail, it can't pull completely apart. In this setup, it would interfere with articulation though and couldn't be a simple flat washer. Just a thought anyway.

I’m very interested in what the final product ends up being. Healthy radii on the inside corners, rolled threads, and post-machining heat-treat are things I’d be looking for on the main shaft. 4140/41L40? 4340?

Adding a large diameter washer to the bottom might be a good idea. It's pretty common for that to be a requirement on suspension components in a lot of racing organizations so that should the plain bearing ever fail, it can't pull completely apart. In this setup, it would interfere with articulation though and couldn't be a simple flat washer. Just a thought anyway.

I’m very interested in what the final product ends up being. Healthy radii on the inside corners, rolled threads, and post-machining heat-treat are things I’d be looking for on the main shaft. 4140/41L40? 4340?

#10

Yeah, the stock arms are pretty awesome for stiffness and weight and beating them in that regard would be tough to do. The only reason I'd look at an arm replacement is if it was adjustable for track width and caster. Even then though, with the X arms and the PSRS you can accomplish the same thing.

. . .

. . .

#13

Evolved Member

iTrader: (1)

I would be in the replacement ball joint. Front lower Control arm. esp if it will do much better than the Whiteline one. Needs a boot to seal it to retain grease etc.

Question for the designers. Can the other small bushing on the front lower control arm ( not the large one in the rear that can be replaced by the PRS one ) be replaced with a sleeved needle bearing ? They are high load capacity. And you can cap the ends as suggested by large washers to retain them. In fact if the washers had a neoprene coating on the inner side, it would be capable of retaining grease so mimicing a sealed bearing.

thoughts?

Question for the designers. Can the other small bushing on the front lower control arm ( not the large one in the rear that can be replaced by the PRS one ) be replaced with a sleeved needle bearing ? They are high load capacity. And you can cap the ends as suggested by large washers to retain them. In fact if the washers had a neoprene coating on the inner side, it would be capable of retaining grease so mimicing a sealed bearing.

thoughts?

#14

Evolved Member

iTrader: (8)

No, you do not want a needle bearing in there. If you use the Offset PSRS for caster, the bore for the bearing in the arm is no longer concentric with the bolt in the subframe. Even if you don't use the offset though, any flex in the subframe or arm would cause uneven loads on a needle bering setup.

You can use a plain bearing though.

Properly sized, they should have no problem with carrying the loads. You can get away with the cheaper and more common narrow bearings too as there really shouldn't be much of an axial load on the bearing so no need for a wide bearing and the movement is about the shaft axis so there is no need for a high-misalignment bearing.

As far as sealing this type of stuff up, it probably won't happen. These types of parts really aren't meant for street cars. You can get "dust caps" for this type of stuff, but it's simply meant to reduce (not stop) the amount of junk getting in. They still need to be cleaned and serviced often.

You can use a plain bearing though.

Properly sized, they should have no problem with carrying the loads. You can get away with the cheaper and more common narrow bearings too as there really shouldn't be much of an axial load on the bearing so no need for a wide bearing and the movement is about the shaft axis so there is no need for a high-misalignment bearing.

As far as sealing this type of stuff up, it probably won't happen. These types of parts really aren't meant for street cars. You can get "dust caps" for this type of stuff, but it's simply meant to reduce (not stop) the amount of junk getting in. They still need to be cleaned and serviced often.

Last edited by 03whitegsr; Jun 22, 2012 at 07:34 AM.

#15

I'm not too worried about sealed bearings. No reason really to run sphericals except on a race car.