Switching Fuel Systems - Dual Pump back to single

#1

Switching Fuel Systems - Dual Pump back to single

So I have had quite a few issues with my fuel system working exactly how I wanted it to over the years. Nothing earth shattering until recently.

My current fuel setup is a blaqops dual pumper with a 255 and I am unsure what they used for the second pump but I think its different than a 255. I am running the progressive boost version, which has a set point where the second pump turns on and then a second set point at which the pump is "full on". So the idea is you have a progressive system that slowly ramps up the second pump to give you a nice smooth transition.

Well here is what I have noticed. The idea behind a progressive second pump is stupid and unneeded. Honestly, just using a hobbs switch is really all you need and the car is spooling fast enough to eat up the fuel anyway, so I don't ever see a reason to ramp up the second pump, just more complexity that isn't needed and I am now a firm believer in a simpler fuel system.

Right now I have my progressive controller almost set to hobbs switch. The 2nd pump comes on at like 2-3 psi and is full on by like 5-6 psi and everything works out very well.

The very first problem I had was the car wanted to lean out on spool up, which really sucked. My tuner eliminated most of this by lower the set points to almost hobb switch style, which I lowered even more for my newest tuner.

Ok first problem solved, but after lots of logging/tuning we discovered that the MAF/MAP tables were so far off that the car never added fuel so tuning played a big part in this too. Also the open loop/closed loop crossover needed adjusting, so those few things all were involved in my spool up issues.

Well we also noticed that my fuel pressure would not go above 50psi at idle so then we found out the 2nd pump had no check valve and fuel was leaking back into the tank. Well I installed a big ol Jegs E85 safe check valve and problem solved, was able to run up to 80psi at idle, maybe more lol. Obviously I turned it back down.

Even now though with all these smaller issues solved I still have always had a much worse fuel pickup problem then stock. Stock we have fuel pickup issues on turns with fuel slosh but the dual pump setup has amplified this and made it really bad. I have "ran out of fuel" at 1/3 tank before where I needed someone to bring me e85. Well this was annoying but not terrible, so I tried to keep the tank at 1/2 tank or more.

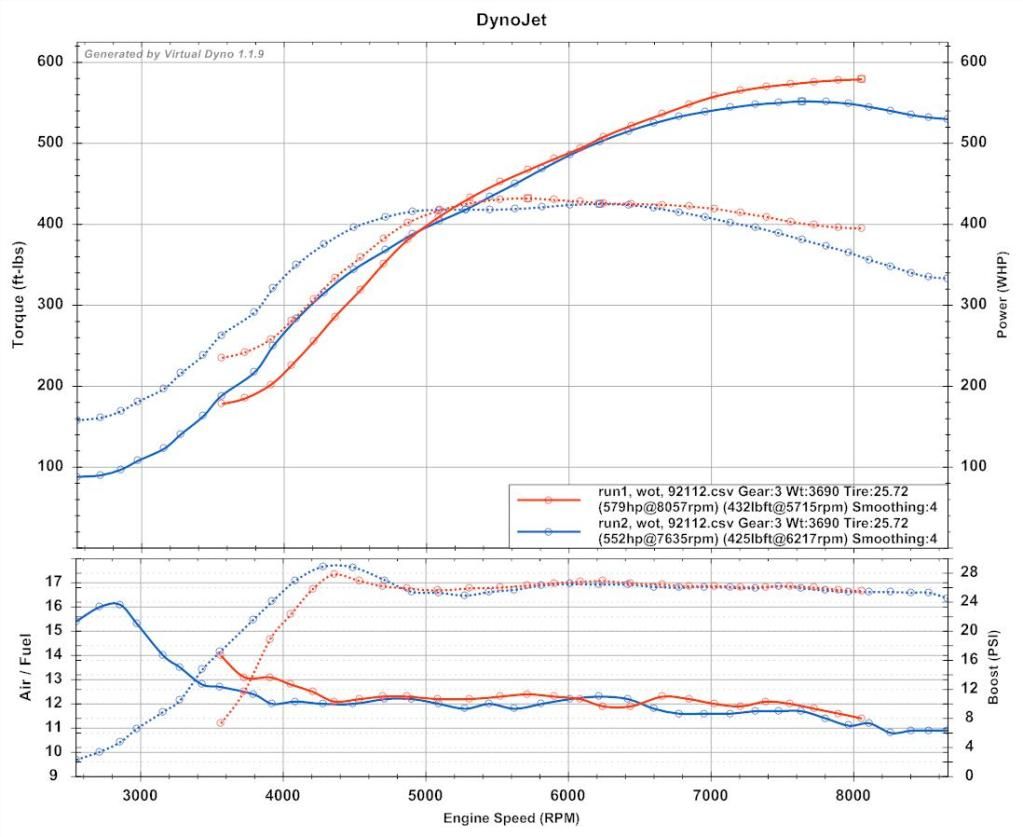

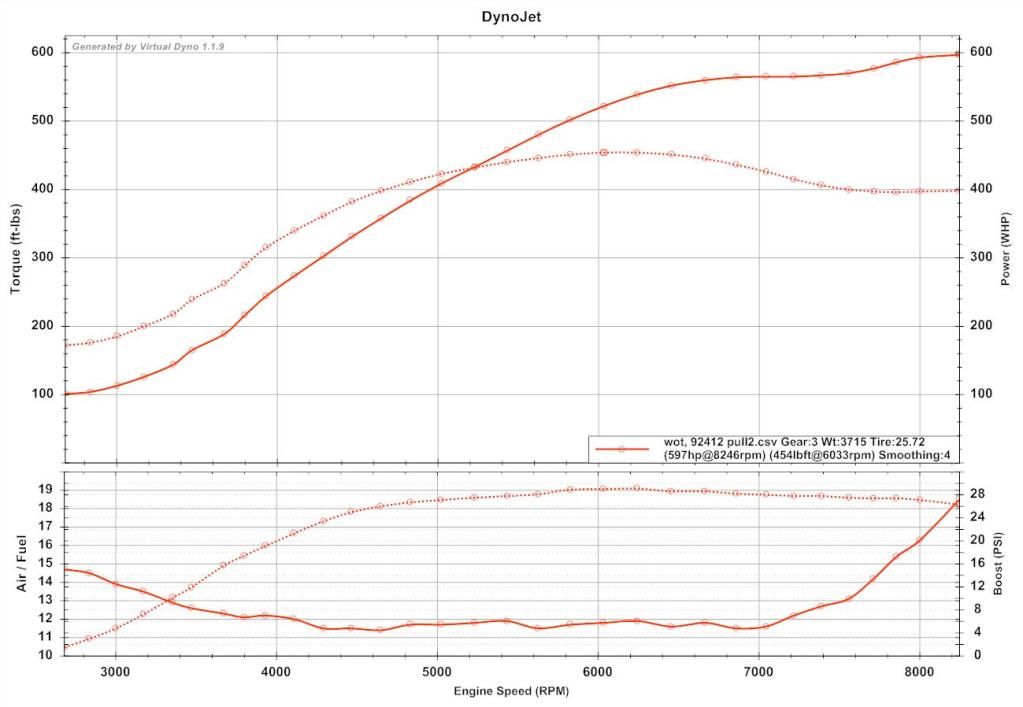

So most recently this was found while logging.

The lean run was at 1/2 tank of fuel, I then put 7.2 gallons in and the car ran the next log, which was perfect. no knock on either but just shows my pick up sucks!

So now I bought this:

My dual pumper setup obviously modified my stock hangar so now I needed a new OEM one. Well it is almost OEM, minus the lines as there was a 255 kit in here that was returned to OEM and those OEM lines were cut and replaced with whats on there, which will get replaced again.

So here is my plan for fueling...

-Wally 400 E85 version

-MAP Fuel Pump install kit

-MAP hardwire kit (run voltage right from battery)

-MAP fuel feed line

-6 AN feed line from rail

Re-use stock feed line for return since its bigger

-Drill out siphon to lower pressure

After seeing Mr. Fred's testing on the fuel feed line we (by we I mean MAP and I) are hoping there are some restrictions in the lines just like the 8/9. Mr. Fred saw almost 10psi of pressure drop I believe after upgrading the lines.

With the lines and fuel siphon mod we are hoping that there is a lot of extra pressure we can alleviate. The idea is that at lower pressures pumps flow a lot more.

The overall goal is to see ~600whp on E85 out of the single pump. After all the issues I have had with the dual pumper I want a nice single pump setup. In the future if I need more fuel pump I will throw on a BAP (kenne bell boost a pump) or simply run a surge tank setup with a giant weldon. I will report back soon with my findings, hopefully next week.

Also Chris Carey ran a Wally 400 before and might switch back, but he had no issues running it to the gas lights, so I am looking forward to this.

For reference: My other fuel mods are DW1300's and a MAP AFPR kit. Pretty basic setup.

Just thought I'd share my setup, issues and plans in hopes I find a solid single pump solution for people making 500-600whp so you don't need to go to a dual pumper.

My current fuel setup is a blaqops dual pumper with a 255 and I am unsure what they used for the second pump but I think its different than a 255. I am running the progressive boost version, which has a set point where the second pump turns on and then a second set point at which the pump is "full on". So the idea is you have a progressive system that slowly ramps up the second pump to give you a nice smooth transition.

Well here is what I have noticed. The idea behind a progressive second pump is stupid and unneeded. Honestly, just using a hobbs switch is really all you need and the car is spooling fast enough to eat up the fuel anyway, so I don't ever see a reason to ramp up the second pump, just more complexity that isn't needed and I am now a firm believer in a simpler fuel system.

Right now I have my progressive controller almost set to hobbs switch. The 2nd pump comes on at like 2-3 psi and is full on by like 5-6 psi and everything works out very well.

The very first problem I had was the car wanted to lean out on spool up, which really sucked. My tuner eliminated most of this by lower the set points to almost hobb switch style, which I lowered even more for my newest tuner.

Ok first problem solved, but after lots of logging/tuning we discovered that the MAF/MAP tables were so far off that the car never added fuel so tuning played a big part in this too. Also the open loop/closed loop crossover needed adjusting, so those few things all were involved in my spool up issues.

Well we also noticed that my fuel pressure would not go above 50psi at idle so then we found out the 2nd pump had no check valve and fuel was leaking back into the tank. Well I installed a big ol Jegs E85 safe check valve and problem solved, was able to run up to 80psi at idle, maybe more lol. Obviously I turned it back down.

Even now though with all these smaller issues solved I still have always had a much worse fuel pickup problem then stock. Stock we have fuel pickup issues on turns with fuel slosh but the dual pump setup has amplified this and made it really bad. I have "ran out of fuel" at 1/3 tank before where I needed someone to bring me e85. Well this was annoying but not terrible, so I tried to keep the tank at 1/2 tank or more.

So most recently this was found while logging.

The lean run was at 1/2 tank of fuel, I then put 7.2 gallons in and the car ran the next log, which was perfect. no knock on either but just shows my pick up sucks!

So now I bought this:

My dual pumper setup obviously modified my stock hangar so now I needed a new OEM one. Well it is almost OEM, minus the lines as there was a 255 kit in here that was returned to OEM and those OEM lines were cut and replaced with whats on there, which will get replaced again.

So here is my plan for fueling...

-Wally 400 E85 version

-MAP Fuel Pump install kit

-MAP hardwire kit (run voltage right from battery)

-MAP fuel feed line

-6 AN feed line from rail

Re-use stock feed line for return since its bigger

-Drill out siphon to lower pressure

After seeing Mr. Fred's testing on the fuel feed line we (by we I mean MAP and I) are hoping there are some restrictions in the lines just like the 8/9. Mr. Fred saw almost 10psi of pressure drop I believe after upgrading the lines.

With the lines and fuel siphon mod we are hoping that there is a lot of extra pressure we can alleviate. The idea is that at lower pressures pumps flow a lot more.

The overall goal is to see ~600whp on E85 out of the single pump. After all the issues I have had with the dual pumper I want a nice single pump setup. In the future if I need more fuel pump I will throw on a BAP (kenne bell boost a pump) or simply run a surge tank setup with a giant weldon. I will report back soon with my findings, hopefully next week.

Also Chris Carey ran a Wally 400 before and might switch back, but he had no issues running it to the gas lights, so I am looking forward to this.

For reference: My other fuel mods are DW1300's and a MAP AFPR kit. Pretty basic setup.

Just thought I'd share my setup, issues and plans in hopes I find a solid single pump solution for people making 500-600whp so you don't need to go to a dual pumper.

#2

Evolving Member

Join Date: Sep 2009

Location: Los Angeles

Posts: 199

Likes: 0

Received 0 Likes

on

0 Posts

I have seen weird things happen with a single Walbro400 with upgraded relay wiring, upgraded fuel rail and AFPR. The voltage would be all over the place and it would make the car run lean. In addition the fuel pressure at idle was 55 psi, and could not be adjusted lower (even with the fuel pump return housing drilled out) Once I removed the relay wiring, the problems went away. Got a constant 13.1 volts almost up to redline. Still trying to get the most out of the fuel system though and exploring other options.

#4

Evolved Member

iTrader: (1)

i have the walbro 400 e85 pump in my car.

i did drill the return to 3/32" but have not removed the tiny cone filter yet. (i will next time i open the tank since i have purchased a new flex fuel hose for the in tank return line).

i didn't know what my base fuel pressure was which is useless/dangerous, so i just dropped the coin for the ams rail and regulator setup. i started the car back up last night. at base pressure (minimum regulator) it was running at ~25psi which is a lot lower than i thought it could go.

i adjusted it to ~47 off vacuum, ~42 on vacuum for now. there is a tiny leak at the return from the regulator i need to fix tonight.

i did drill the return to 3/32" but have not removed the tiny cone filter yet. (i will next time i open the tank since i have purchased a new flex fuel hose for the in tank return line).

i didn't know what my base fuel pressure was which is useless/dangerous, so i just dropped the coin for the ams rail and regulator setup. i started the car back up last night. at base pressure (minimum regulator) it was running at ~25psi which is a lot lower than i thought it could go.

i adjusted it to ~47 off vacuum, ~42 on vacuum for now. there is a tiny leak at the return from the regulator i need to fix tonight.

#5

Evolving Member

iTrader: (8)

Join Date: Aug 2005

Location: TN

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

Im running a single w400 now myself. Although im using oem wiring, as im running just 93 now and didnt have to squeeze every ounce out possible. Ive never been a fan of a hacked up oem hanger with twin pumps since it only works well with a full tank of gas. Nice to share your findings.

Trending Topics

#8

Car is back home!

Not a whole lot to show really, its a fuel pump in the fuel tank lol.

So few notes...

Once MAP had all the extra fittings sorted out, the lowest fuel pressure they saw was 65psi at idle. This is with the return siphon drilled out, unsure how much but as much as possible without screwing **** up. They also drilled out the pressure relief on the hanger too.

One thing they didn't do was turn my feed line into the return. It's only 1/16th bigger anyway, but with the stock hanger it just wasn't happening.

So now I have the hard wired wally 400 e85 version in the tank with a 6AN feed line and new Fuel lab fuel filter.

MAP was able to get idle pressure down to 50psi (without vac, with vac was 43 or whatever) by drilling out the fpr insert. I didn't have the bigger one so they modded the one that was in there. Then problem solved...so far everything is good.

I did have a scare on the way home. I was barely able to shift into 3rd and 5th was ALMOST impossible to get into. So i immediately knew my shifter linkage was all goofed up somehow. At first I thought maybe MAP dropped something on it or some weird **** so I was like WTF. When I got home though I noticed the return line sank low enough to get in between everything. One zip tie and we are back in business now!

HOpefully get some logs and tuning in this weekend. With a new base fuel pressure I will need some work from Baka I think!

Not a whole lot to show really, its a fuel pump in the fuel tank lol.

So few notes...

Once MAP had all the extra fittings sorted out, the lowest fuel pressure they saw was 65psi at idle. This is with the return siphon drilled out, unsure how much but as much as possible without screwing **** up. They also drilled out the pressure relief on the hanger too.

One thing they didn't do was turn my feed line into the return. It's only 1/16th bigger anyway, but with the stock hanger it just wasn't happening.

So now I have the hard wired wally 400 e85 version in the tank with a 6AN feed line and new Fuel lab fuel filter.

MAP was able to get idle pressure down to 50psi (without vac, with vac was 43 or whatever) by drilling out the fpr insert. I didn't have the bigger one so they modded the one that was in there. Then problem solved...so far everything is good.

I did have a scare on the way home. I was barely able to shift into 3rd and 5th was ALMOST impossible to get into. So i immediately knew my shifter linkage was all goofed up somehow. At first I thought maybe MAP dropped something on it or some weird **** so I was like WTF. When I got home though I noticed the return line sank low enough to get in between everything. One zip tie and we are back in business now!

HOpefully get some logs and tuning in this weekend. With a new base fuel pressure I will need some work from Baka I think!

#9

Evolved Member

iTrader: (1)

that's quite strange. even with the walbro 400 e85 pump, i can get my fuel pressure pretty low. i'm running stock wiring so 9v at idle i guess?

on vac i'm seeing 38ish psi now at the regulator and i only drilled the return to 3/32"

sounds like you are 12v all the time.

on vac i'm seeing 38ish psi now at the regulator and i only drilled the return to 3/32"

sounds like you are 12v all the time.

#11

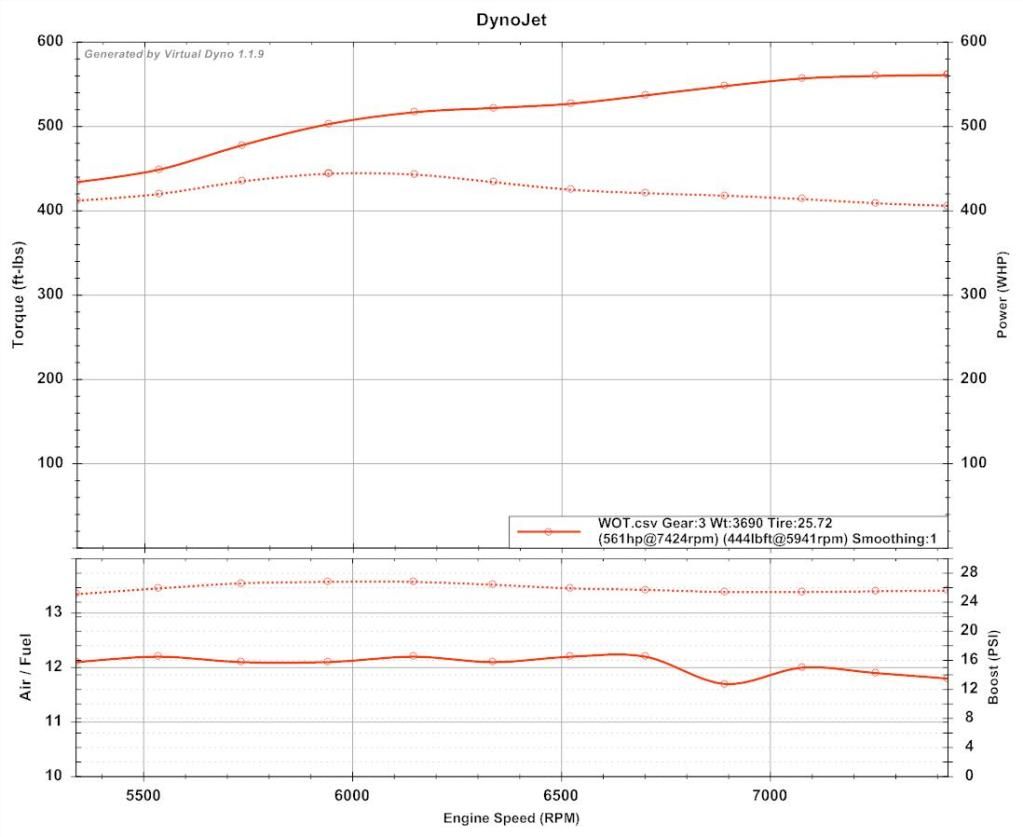

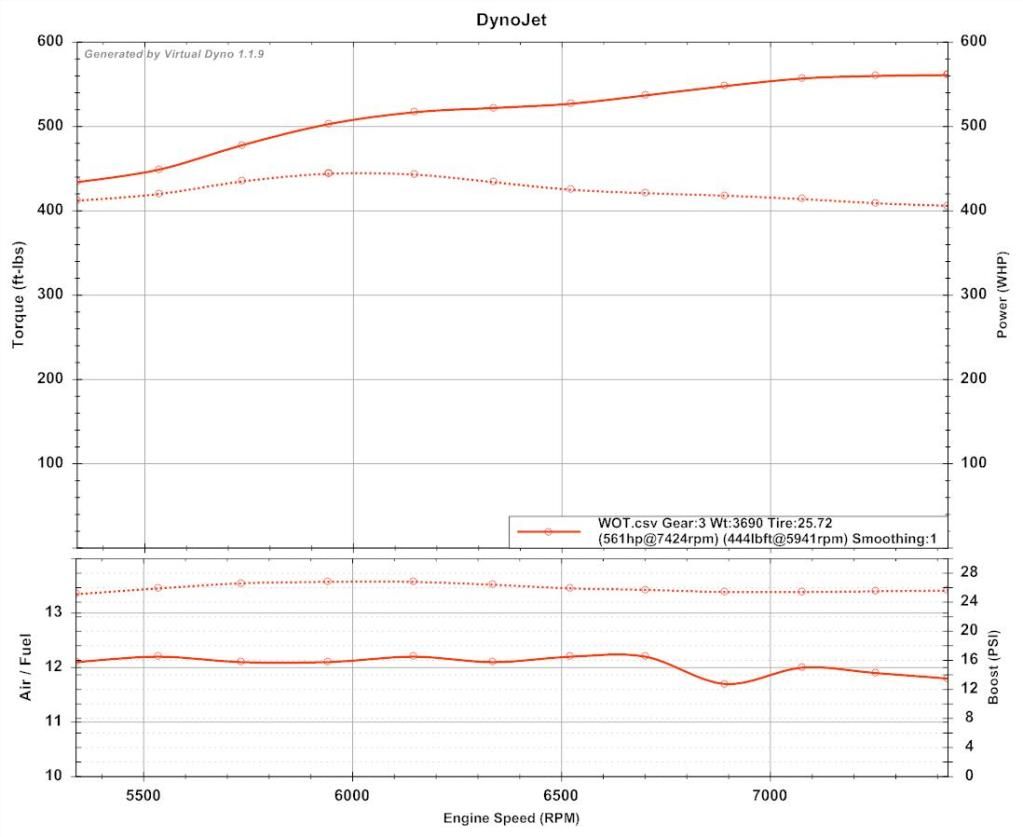

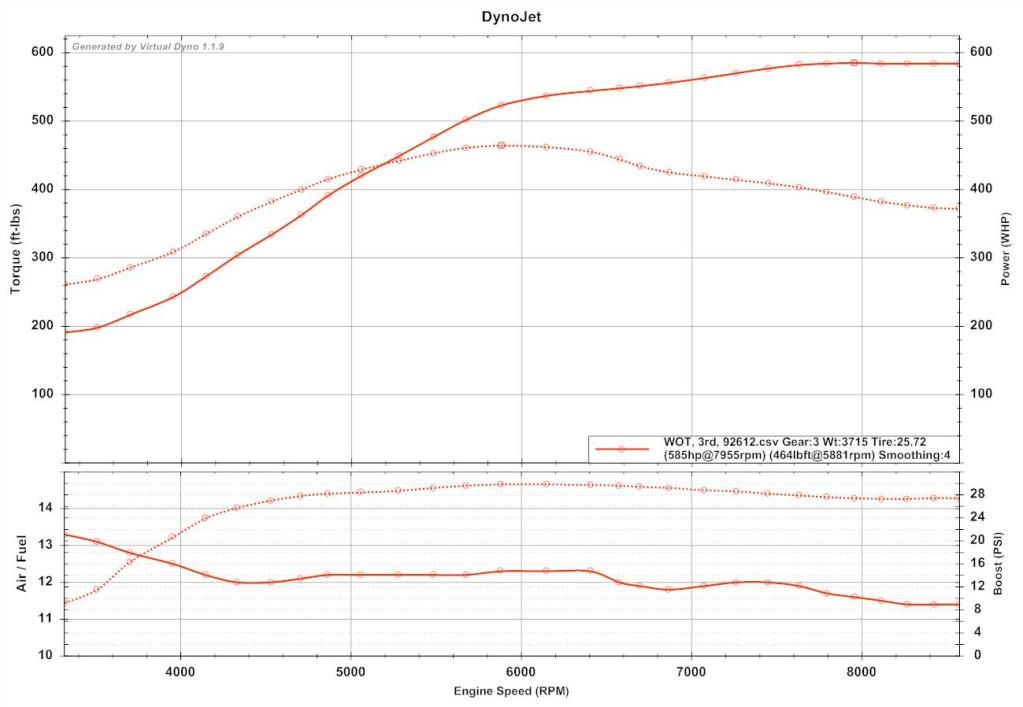

Did more logs today! Car is running great.

Did a partial WOT run, mostly watching AFR's...looked good!

Time to turn the wick up, see what one wally 400 can do.

Oh, biggest thing! I went up to 15psi or so at near empty (maybe an 1/8th of a tank), I had fuel! yay...new fuel system so far so good.

Did a partial WOT run, mostly watching AFR's...looked good!

Time to turn the wick up, see what one wally 400 can do.

Oh, biggest thing! I went up to 15psi or so at near empty (maybe an 1/8th of a tank), I had fuel! yay...new fuel system so far so good.

#13

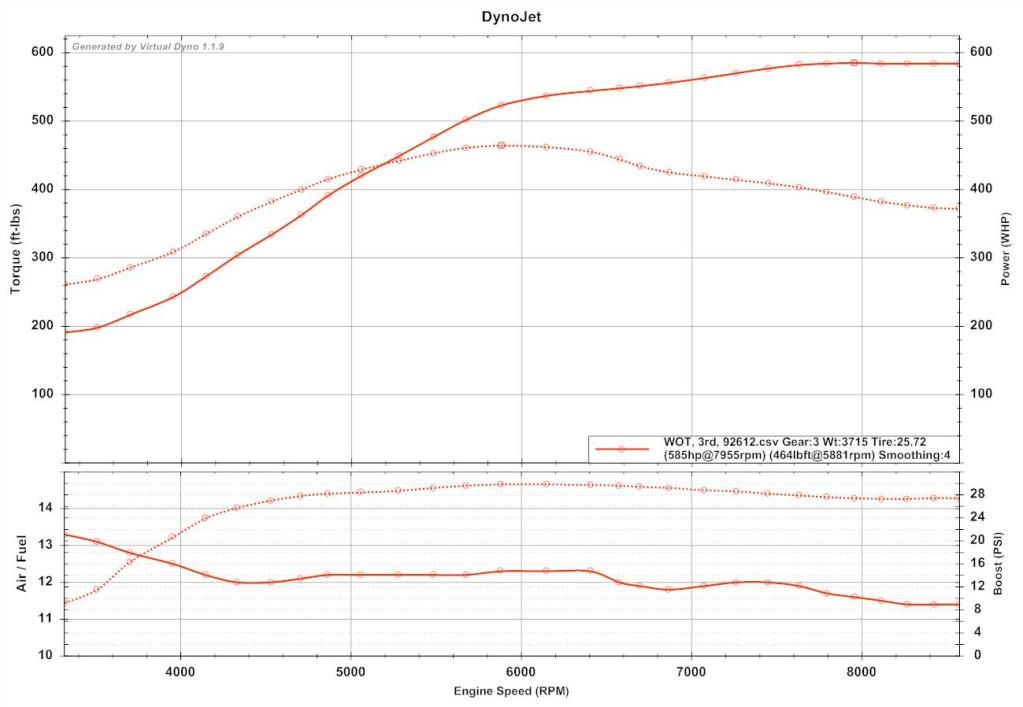

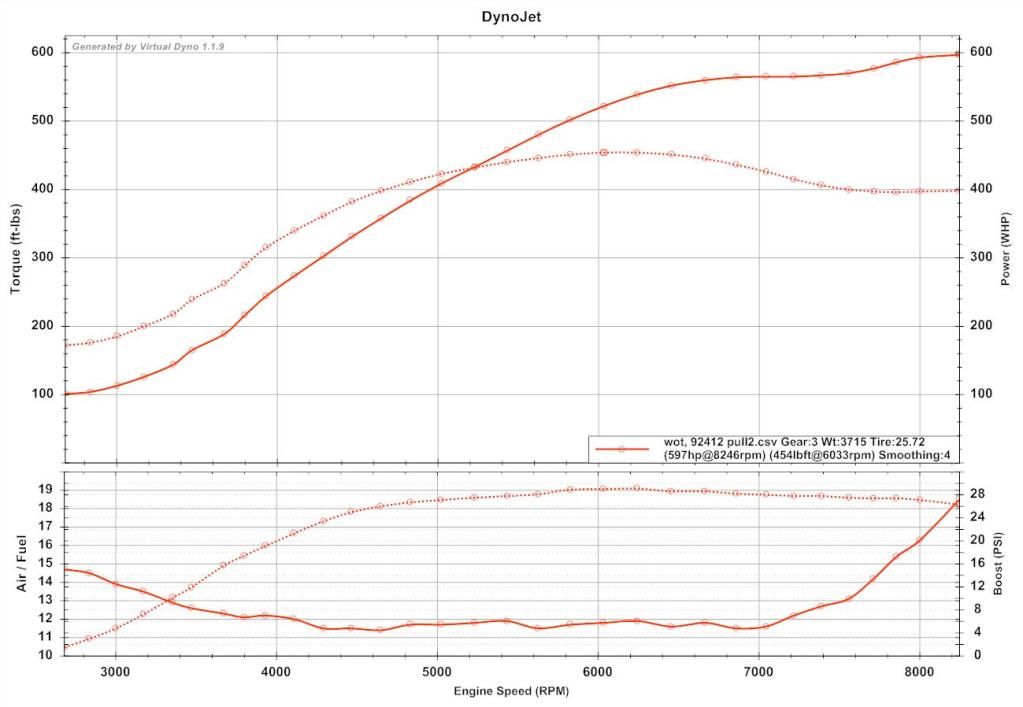

Forgot to update this thread.

Plenty of fuels with this pump on e85! I'd say almost 650whp on this pump with my setup is doable. I've been up as high as 630whp on a cold night with fuel to spare.

However, at lower fuel levels (1/4) I still get fuel starvation and the car leans out. The car makes too much power and empties the fuel basket is what it looks like is happening. See here.

So, when I beat on the car, 1/2 tank and above is kinda necessary to be safe.

Plenty of fuels with this pump on e85! I'd say almost 650whp on this pump with my setup is doable. I've been up as high as 630whp on a cold night with fuel to spare.

However, at lower fuel levels (1/4) I still get fuel starvation and the car leans out. The car makes too much power and empties the fuel basket is what it looks like is happening. See here.

So, when I beat on the car, 1/2 tank and above is kinda necessary to be safe.

Thread

Thread Starter

Forum

Replies

Last Post

420a-t

For Sale/WTB - Engine / Drivetrain / Power

2

Apr 11, 2017 07:08 PM

SurfGuruJeff

Evo X Engine / Turbo / Drivetrain

6

Jan 26, 2017 05:34 PM

Dynotech Tuning

Evo Engine / Turbo / Drivetrain

39

Dec 3, 2016 11:04 AM

Erik@MIL.SPEC

E85 / Ethanol

7

Nov 11, 2008 12:46 PM