Crunchy Trans Right Out of The Box?

#1

Thread Starter

Gold Sponsor

iTrader: (2)

Joined: Dec 2012

Posts: 195

Likes: 11

From: Colorado Springs, CO.

Crunchy Trans Right Out of The Box?

- Have an EVO 10 with a trans that likes to grind into 3rd gear in that cold morning?

- Have an EVO 8-9 which seems to always grind 5th gear at the track no matter what you do or how many times the synchro is replaced?

We have figured out why this happens. The synchro timing from the factory is sloppy and not synched correctly. Several factors like the slider ramps, synchro keys and synchro rings themselves can be a little off in the timing causing an unpleasant shift.

Synchro Blueprinting

An important check missed by many builders is proper synchro operation. A synchronizer is pretty ingenious in its design and requires perfect timing and application of force in just the right spot in order to operate efficiently. When people blindly install new synchros, they are not always in perfect alignment and this can seriously affect life and performance.

At Jacks Transmissions, we spend an enormous amount of time making absolutely sure your synchro is set up correctly. Most people will polish them, maybe add more oil channels, but you never hear of anyone changing the preload timing and tooth contact area to allow for superior operation like us. Please note that some of our competitors are now stating this is old news and they have been doing this for years. That is not true and they absolutely DO NOT perform the same work as us. It's funny how they say they do this complex work, yet you never heard of it until now. A good question to ask is, if they spend the time to do this, why didn't they mention this before? It's because they never did it before, and they don't do it now, period. We have seen their units, and we can tell you they do no detail work to the rings of any kind. Polishing doesn't count as detail work, and adding oil to the synchro doesn't work either as the synchro needs friction in order to work efficiently. Adding oil to them will make them feel notchy as they have to work harder to squeeze the oil away.

We believe, and this may sound scary, that most trans builders don't know exactly how a synchro works. It can be pretty complicated and I have talked with several people who have repaired manual transmissions. They give me a 'deer in the headlights' look when I try to go into detail, get their opinion about how a synchro works and how to improve the design. Most trans builders do not have the engineering mentality we have here. We do these improvements as it's terribly important for the synchro to live and operate as intended. We believe this is why our transmissions shift, as some would say, 'like butter' (as in it shifts so smooth it feels like a hot knife through butter). This is a great compliment and we appreciate this very much as it shows the time we spend on your synchros does some good and people notice!

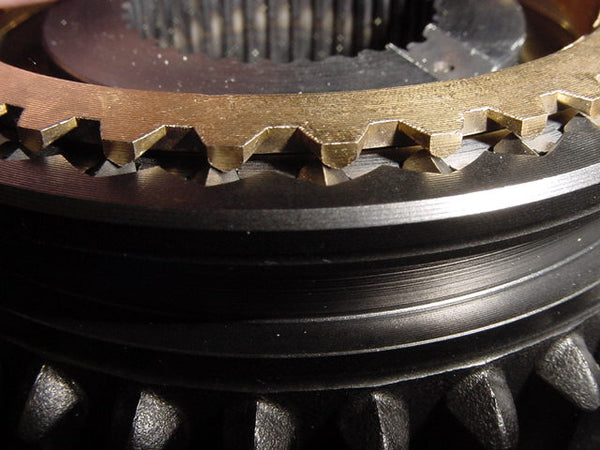

The first thing we check, and we find that we have to modify the most, is the contact between the synchro ring teeth and the slider teeth.

Proper contact of the teeth while the synchro is preloaded by the springs and keys, along with correct contact with the slider, will make a big difference in not only the life of the synchro, but how nice it feels to the driver! Below I made some examples of what we see daily here with BRAND NEW factory OEM synchros if we were to blindly install them untouched.

Example below of proper tooth contact if all is perfect in a perfect world. ...or when Jacks Transmissions is done making it right below:

Synchros work by the change in force to the teeth. When the synchro is loaded and trying to synchronize the assembly, the pic above is how the teeth should line up and the arrows show the direction of the force being applied.

Once the part is synchronized, the force changes and you then get a direct 'UP' and 'DOWN' force to the teeth like the pic below. This will allow the teeth to give way and to 'slip' past each other. When the slider passes the synchro ring, it will then engage (lock) the gear in place. That's how it's supposed to work and look.

Below I have some examples of what we noticed to be a problem, which is more common than you may think.

The picture below shows how the teeth make contact with most EVOIII, and HD (Heavy Duty) DSM 3-4 synchros, if you were to blindly install them:

The teeth are preloaded too early and the assembly believes they are already touching due to poor timing. This is not good as the keys which preload the synchro can give way too soon losing the synchronized motion of the gear, and will cause a slight crunch (grind) when you shift normally at low RPM.

We have to modify several parts to cure this problem. We machine the keys for a later preloading, and then machine the stops on the rings to allow for more movement so it will mesh with the slider teeth more accurately. EVOIII 3rd gears are known for their low RPM 'crunch'. We fix this on ALL of our rebuilds and we now include the modifications to the keys to prevent this and allow for proper contact on our EVOIII conversion kits too! When you buy our gear cluster builds, or complete trans rebuild, we will give attention to detail to solve issues like this.

The next pic below is what we find in your EVO 8-9 units. The hub is too narrow and will not allow the synchro ring to move far enough for the teeth to make full contact. They instead will make contact too late and this will make the assembly 'slip' past early and crash the slider into the gear engagement teeth (grind). This is a serious problem with 3rd, 4th and 5th in the EVO 8-9 at high RPM and high load conditions. Wonder why your 5th gear grinds so easily? Does your 5th grind in the new trans you just got from the guy who claims he does the same detail work as us? This is why, and we solve this problem by modifying the synchro hub in your EVO. It makes a big difference and feels so much better!

As an experiment, I took an EVO 8 trans that had a 5th gear which was grinding terribly. I widened the hub and made sure the synchro was making proper contact. Without changing any of the parts and reusing the whole assembly, which was grinding badly before, 5th no longer grinds and works perfectly even at high RPM and under some serious abuse! Nice to have a brother as a guinea pig with his EVO 8 and that verified some time ago that my logic behind proper tooth contact is correct and works! If your 5th grinds, it may not be bad, but out of time.

For those with an EVO 8-9, it gets worse! In the picture below, the synchro will wear faster due to the small area used. The wear will then make the contact point smaller and even though the assembly is otherwise healthy, it will slip past every time giving you an annoying grind very early on in the units life.

This is only one part of many other pieces of your synchro. Trying to explain common issues as simply as possible is difficult, but we hope that you get more of an understanding as to the time we spend on your synchros! The teeth on the synchro ring is something overlooked by many, but those teeth are very important and must be perfect to give you that quality shift you want. We take great pride in our products and it feels great when people compliment us on how nice their trans shifts. Paying attention and understanding the complexities of synchro operation allows us to do a lot more than your average transmission shop! We believe that the time spent is a good thing and we hope you notice it when you shift our trans.

Home / Synchro Blueprinting

Last edited by Jacks Transmissions; Feb 27, 2013 at 02:56 PM.

#3

But wait, for you EVO 8-9 owners, it gets worse! The synchro will wear faster due to the small area in which it's making contact. The wear will then make the contact point smaller and even though the assembly is otherwise healthy, it will slip past every time giving you an annoying grind very early on in the units life.

So how do you fix this?

So how do you fix this?

#6

Thread Starter

Gold Sponsor

iTrader: (2)

Joined: Dec 2012

Posts: 195

Likes: 11

From: Colorado Springs, CO.

But wait, for you EVO 8-9 owners, it gets worse! The synchro will wear faster due to the small area in which it's making contact. The wear will then make the contact point smaller and even though the assembly is otherwise healthy, it will slip past every time giving you an annoying grind very early on in the units life.

So how do you fix this?

So how do you fix this?

We machine the outer edge of the synchro ring keys to do this. It's a bit time consuming, but they work great after we are finished.

Trending Topics

#11

Thread Starter

Gold Sponsor

iTrader: (2)

Joined: Dec 2012

Posts: 195

Likes: 11

From: Colorado Springs, CO.

Thread

Thread Starter

Forum

Replies

Last Post

Jacks Transmissions

Jacks Transmissions

0

Jan 30, 2015 01:19 PM

hollywood_X

Mitsubishi TC-SST Discussion

13

Oct 9, 2012 02:49 PM