Todds '03 evo 8 NASA TTC build!

#31

I've been waiting for the day someone runs an Evo 8 in TTC. Cool build guys!

You can thank me for being able to coat the exhaust pieces. I fought and fought with Greg over the ruling for that. The no-points mod previously only allowed for wrapping exhaust parts. Greg claimed if someone sprayed or coated a piece then inspectors wouldn't be able to tell if it was still OEM.

I fought and fought with Greg over the ruling for that. The no-points mod previously only allowed for wrapping exhaust parts. Greg claimed if someone sprayed or coated a piece then inspectors wouldn't be able to tell if it was still OEM.

Also, you guys do know that adding A-pillar gussets is +2 right? Personally I would hold off on that and spend those 2 points on something else.

You can thank me for being able to coat the exhaust pieces.

I fought and fought with Greg over the ruling for that. The no-points mod previously only allowed for wrapping exhaust parts. Greg claimed if someone sprayed or coated a piece then inspectors wouldn't be able to tell if it was still OEM.

I fought and fought with Greg over the ruling for that. The no-points mod previously only allowed for wrapping exhaust parts. Greg claimed if someone sprayed or coated a piece then inspectors wouldn't be able to tell if it was still OEM.

Also, you guys do know that adding A-pillar gussets is +2 right? Personally I would hold off on that and spend those 2 points on something else.

Second, damn you and your wisdom about the A-pillar gussets!

The rules were kinda vague regarding gussets away from the tube ends, so I sent a message to the Texas NASA TT officials to double check. Well, they do cost two points. Every part of the car is considered the "chassis" so welding the roll cage to anything else costs 2 points. I'm glad you said something.

The rules were kinda vague regarding gussets away from the tube ends, so I sent a message to the Texas NASA TT officials to double check. Well, they do cost two points. Every part of the car is considered the "chassis" so welding the roll cage to anything else costs 2 points. I'm glad you said something.Anyway, there will be an update soon with recent improvements.

#33

updates coming when todd drops the car off from his day at MSR friday!

1) getting the replacement suspension parts it needs on the driver side and we are doing the energy suspension master bushing kit on everything

2) We are changing the mods we have to go away from the lowering springs to a shep modified rear diff to get rid of the understeer in the car, and also either adding an air intake, or getting rid of the cat for the last point.

3) we are getting 125lbs of steel plate to add behind the passenger seat to ballast it up to the proper weight

4) relocating the battery behind the driver seat to lower the CG a little since its still a full size battery. this will also help move the car to a more even weigh distribution and reduce the moment of inertia in the yaw axis (should help steering response and improve vehicle rotation.

5) painting the interior

1) getting the replacement suspension parts it needs on the driver side and we are doing the energy suspension master bushing kit on everything

2) We are changing the mods we have to go away from the lowering springs to a shep modified rear diff to get rid of the understeer in the car, and also either adding an air intake, or getting rid of the cat for the last point.

3) we are getting 125lbs of steel plate to add behind the passenger seat to ballast it up to the proper weight

4) relocating the battery behind the driver seat to lower the CG a little since its still a full size battery. this will also help move the car to a more even weigh distribution and reduce the moment of inertia in the yaw axis (should help steering response and improve vehicle rotation.

5) painting the interior

#34

this week we removed Todds front control arms and bead blasted them and pressed the new energy suspension bushings into them. also replaced the driver side front knuckle to get the camber back to where it should be. replacing both parts took the camber back to the negative finally  we are going to put some adjustable camber plates on when we remove the springs to get the rest of the camber we need.

we are going to put some adjustable camber plates on when we remove the springs to get the rest of the camber we need.

when the shep rear diff gets here we will remove the rear suspension and install all the bushings back there and replace a bad CV dust ring.

we are going to put some adjustable camber plates on when we remove the springs to get the rest of the camber we need.

we are going to put some adjustable camber plates on when we remove the springs to get the rest of the camber we need.

when the shep rear diff gets here we will remove the rear suspension and install all the bushings back there and replace a bad CV dust ring.

#35

well, just in time for the ECR toy run, we got the shep rear diff in, and while putting it in, we pressed the energy suspension rear diff bushings in, along with replacing the passenger side axle which had a missing dust cover which was leaking.

here are the mustache bar bushings in place:

and the side mounts before paint:

and the new diff in place, this is the 12 plate upgrade shep offers. :

the car is good to go for the ECR toy run now, just have to take the interior out and paint it before next years NASA events start which is late january!

here are the mustache bar bushings in place:

and the side mounts before paint:

and the new diff in place, this is the 12 plate upgrade shep offers. :

the car is good to go for the ECR toy run now, just have to take the interior out and paint it before next years NASA events start which is late january!

#37

last week we got some more stuff checked off the list! brought the car to Lewisville Mitsubishi who is helping us align the back of the frame which needs about a 1/4" to a 1/2" pull to get the rear camber where we want. replacing the bent suspension components allowed it to go from

+2* to -.5* so we are only .9* off from what we want. the frame pull will do the rest. After Lewisville Mitsubishi is done, the car comes back for its NASA graphics and the last few changes.

things left to do:

1)paint interior

2)relocate battery

3)add ballast behind seat

4) put in a test pipe + tune it!

heres the car at the ECR toy Run last saturday:

by changing out the lowering springs for a shep 12 plate rear diff and getting the alignment much closer, Todd managed to shave off 6 seconds per lap from the last months ECR event!!!!

Todd said the rear Diff let him throttle out of corners now rather then pushing out of every corner. he is only 1 second off the NASA TTC time at the last event now, so we are very close to having a winning car now!

+2* to -.5* so we are only .9* off from what we want. the frame pull will do the rest. After Lewisville Mitsubishi is done, the car comes back for its NASA graphics and the last few changes.

things left to do:

1)paint interior

2)relocate battery

3)add ballast behind seat

4) put in a test pipe + tune it!

heres the car at the ECR toy Run last saturday:

by changing out the lowering springs for a shep 12 plate rear diff and getting the alignment much closer, Todd managed to shave off 6 seconds per lap from the last months ECR event!!!!

Todd said the rear Diff let him throttle out of corners now rather then pushing out of every corner. he is only 1 second off the NASA TTC time at the last event now, so we are very close to having a winning car now!

#38

one other thing to note, the hankook RS3 tires have held up brilliant thus far. the front right tire is worn the most so we will flip it off the rim and move it to the rear left (least worn).

also the front pads are done, so 5 track days and approx 8 hours of heavy track time is what a set of hawk blues will do. pictures once it gets back from the frame place

also the front pads are done, so 5 track days and approx 8 hours of heavy track time is what a set of hawk blues will do. pictures once it gets back from the frame place

#40

more updates to todds car!

lewisville mitsubishi helped us by pulling the frame straight in the rear over christmas break. the subframe in the back was pulled to the driver side about a half inch and it fixed the alignment issues we were having with camber. alignment is now back to exactly what we wanted. Lewisville mitsubishi also provided us with the alignment to our spec.

with that checked off the list, next up is the interior. virgil and i stripped the interior back out of the car to paint everything. we spent a lot of the day scrubbing, cleaning vacuuming every square inch of the interior. thus far we have done the trunk and back seat/deck lid.

trunk before:

trunk after:

and the back seat thus far:

we ran out of primer though, so the rest will be done later this week.

virgil was able to apply the graphics and numbers today as well. so the exterior is done:

next on the list before the first NASA day is:

1) ballast. todd already made the plates, so we just have to mount them tomorrow

2) battery relocation kit was ordered, and will mount that when the interior is done being painted.

3)interior back in

4)front pads

5)tune again with the wastegate actuator adjusted properly.

lewisville mitsubishi helped us by pulling the frame straight in the rear over christmas break. the subframe in the back was pulled to the driver side about a half inch and it fixed the alignment issues we were having with camber. alignment is now back to exactly what we wanted. Lewisville mitsubishi also provided us with the alignment to our spec.

with that checked off the list, next up is the interior. virgil and i stripped the interior back out of the car to paint everything. we spent a lot of the day scrubbing, cleaning vacuuming every square inch of the interior. thus far we have done the trunk and back seat/deck lid.

trunk before:

trunk after:

and the back seat thus far:

we ran out of primer though, so the rest will be done later this week.

virgil was able to apply the graphics and numbers today as well. so the exterior is done:

next on the list before the first NASA day is:

1) ballast. todd already made the plates, so we just have to mount them tomorrow

2) battery relocation kit was ordered, and will mount that when the interior is done being painted.

3)interior back in

4)front pads

5)tune again with the wastegate actuator adjusted properly.

Last edited by KevinD; Jan 3, 2012 at 08:02 PM.

#41

alright! interior is almost completely done! we got all the paint work done and got the interior back in. all thats left inside is a rear view mirror and the roll cage padding.

the painted rear half:

next up todd mounted the ballast behind the passenger seat:

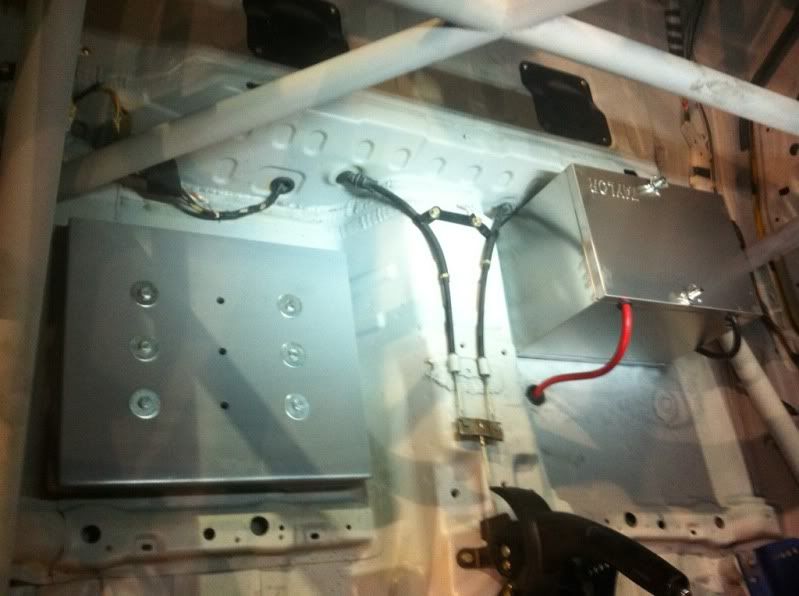

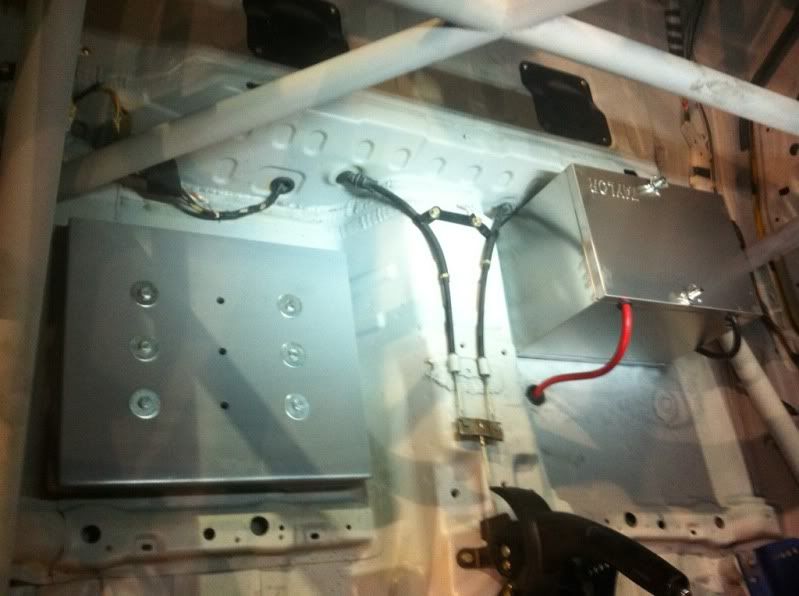

followed by the battery relocation kit:

the back of the car as it sits now:

and the interior going back in:

to do list still:

tow hooks

roll cage padding

retune

front brake pads

bleed brakes

the painted rear half:

next up todd mounted the ballast behind the passenger seat:

followed by the battery relocation kit:

the back of the car as it sits now:

and the interior going back in:

to do list still:

tow hooks

roll cage padding

retune

front brake pads

bleed brakes

#42

got some more work done on Todds car today!

front brakes were worn down last time out at the track so it was time to replace them:

this was after 5 track days with a total of roughly 9 hours on them. plus some street driving over the past 2-3 months. the rear pads have plenty of life left, so this puts the front pads at about 270/set/5 track days = 54$/track day (4-5 20 min sessions) for brake pads on a car prepped like this.

we also gave the fluid a flush but the issues with brake fade were obviously due to no pad left.

next, Caleb installed the front tow hook:

we will be doing the rear tow hook tomorrow, and virgil is going to make the tow stickers for it. getting closer and closer to full track ready.

I spent the evening installing the roll bar padding for the cage near the driver:

last, before cars and coffee, i noticed hearing a tinging sound after the car was shut off before it left for C+C. i didn't think anything of it until about 6 hours later when i thought it could be the turbo blades hitting something. today i removed the manifold to get it recoated and i noticed the V band for the hotside had either broke off or vibrated off :O this is why we safety wire everything on track cars. bolts come loose so often when heated for extended periods of time, and crazy things happen.

on a side note, the basic ceramic coating SPC does doesn't hold up to track use. after talking with michael at SPC, he said to use the tungsten or black ceramic coating for track cars. hes going to redo the work he did on this car, but lesson learned on the ceramic coating....

we are also going to swap the hotside over to a 10.5 from an '05 car to try and pick up a few HP.

front brakes were worn down last time out at the track so it was time to replace them:

this was after 5 track days with a total of roughly 9 hours on them. plus some street driving over the past 2-3 months. the rear pads have plenty of life left, so this puts the front pads at about 270/set/5 track days = 54$/track day (4-5 20 min sessions) for brake pads on a car prepped like this.

we also gave the fluid a flush but the issues with brake fade were obviously due to no pad left.

next, Caleb installed the front tow hook:

we will be doing the rear tow hook tomorrow, and virgil is going to make the tow stickers for it. getting closer and closer to full track ready.

I spent the evening installing the roll bar padding for the cage near the driver:

last, before cars and coffee, i noticed hearing a tinging sound after the car was shut off before it left for C+C. i didn't think anything of it until about 6 hours later when i thought it could be the turbo blades hitting something. today i removed the manifold to get it recoated and i noticed the V band for the hotside had either broke off or vibrated off :O this is why we safety wire everything on track cars. bolts come loose so often when heated for extended periods of time, and crazy things happen.

on a side note, the basic ceramic coating SPC does doesn't hold up to track use. after talking with michael at SPC, he said to use the tungsten or black ceramic coating for track cars. hes going to redo the work he did on this car, but lesson learned on the ceramic coating....

we are also going to swap the hotside over to a 10.5 from an '05 car to try and pick up a few HP.

#44

I think 3 of the 5 track days were at Eagles Canyon, which wears pads at 2x the regular rate.

So, the $54/day wear rate is probably too pessimistic. If its double the wear rate for 3 ECR days, it'd be more like 8 'regular' trackdays. That makes out to $34/day... thats cheap!

So, the $54/day wear rate is probably too pessimistic. If its double the wear rate for 3 ECR days, it'd be more like 8 'regular' trackdays. That makes out to $34/day... thats cheap!

got some more work done on Todds car today!

front brakes were worn down last time out at the track so it was time to replace them:

this was after 5 track days with a total of roughly 9 hours on them. plus some street driving over the past 2-3 months. the rear pads have plenty of life left, so this puts the front pads at about 270/set/5 track days = 54$/track day (4-5 20 min sessions) for brake pads on a car prepped like this.

we also gave the fluid a flush but the issues with brake fade were obviously due to no pad left.

front brakes were worn down last time out at the track so it was time to replace them:

this was after 5 track days with a total of roughly 9 hours on them. plus some street driving over the past 2-3 months. the rear pads have plenty of life left, so this puts the front pads at about 270/set/5 track days = 54$/track day (4-5 20 min sessions) for brake pads on a car prepped like this.

we also gave the fluid a flush but the issues with brake fade were obviously due to no pad left.